jakeparsons03

Member

Hello,

I am putting together a system that I have never done before and I want to make sure that I am doing this right. If someone could give me a sanity check.

So, at a client facility they have both control logix and deltaV systems. We are putting in a new 1756-EN2T remote PLC extension on a L82 controller for a new system we are putting in (System A).

The issue is this. We have a second system that is completely unrelated to System A. We can call it System B. System B is an extension onto an existing system controlled by a DeltaV PLC. The thing is is that the physical location of System B is going is nowhere near the DeltaV PLC but it is very close to our new EN2T remote rack that we are putting in for System A. What I want to do is tie in all of the points to our AB remote rack then push them over network to the DeltaV system.

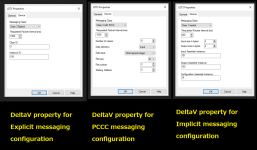

Now, from the research I have done, AB and DeltaV can integrate natively over Ethernet/IP. My problem is, is that I have never touched a deltaV PLC so I am unsure of how this all comes together (luckily I do not have to do the programming but I need the system requirements to be there for someone else to do the programming).

So they already have VIM2 M-series card (short black one not the fancy grey and black card). It looks like that can do Ethernet/IP. Is that all of the system requirements they need to do this? Do they just add an allen bradley driver into an IO tree similar to RSLogix?

I am putting together a system that I have never done before and I want to make sure that I am doing this right. If someone could give me a sanity check.

So, at a client facility they have both control logix and deltaV systems. We are putting in a new 1756-EN2T remote PLC extension on a L82 controller for a new system we are putting in (System A).

The issue is this. We have a second system that is completely unrelated to System A. We can call it System B. System B is an extension onto an existing system controlled by a DeltaV PLC. The thing is is that the physical location of System B is going is nowhere near the DeltaV PLC but it is very close to our new EN2T remote rack that we are putting in for System A. What I want to do is tie in all of the points to our AB remote rack then push them over network to the DeltaV system.

Now, from the research I have done, AB and DeltaV can integrate natively over Ethernet/IP. My problem is, is that I have never touched a deltaV PLC so I am unsure of how this all comes together (luckily I do not have to do the programming but I need the system requirements to be there for someone else to do the programming).

So they already have VIM2 M-series card (short black one not the fancy grey and black card). It looks like that can do Ethernet/IP. Is that all of the system requirements they need to do this? Do they just add an allen bradley driver into an IO tree similar to RSLogix?