BHEKI

Member

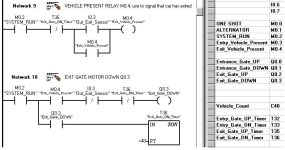

Im new to PLC programming and im trying to write a program which will open a boom(that is running a motor forward), stop and close the boom(reverse the dc motor) maybe after 10second.

Im working on a small project which monitors the cars that are coming inside the car park, as they come to a car park they must be counted and also be decremented as they get out of the parking lot. if the number of cars entering the car park equal the number of parking lot the boom on the entry side must not be activated at all until one or more cars leaves the car park.

I need help on how I can first be able to program one boom gate as to open, stop and close after. The type of PLC Im using is SIEMENS S7-200

Im working on a small project which monitors the cars that are coming inside the car park, as they come to a car park they must be counted and also be decremented as they get out of the parking lot. if the number of cars entering the car park equal the number of parking lot the boom on the entry side must not be activated at all until one or more cars leaves the car park.

I need help on how I can first be able to program one boom gate as to open, stop and close after. The type of PLC Im using is SIEMENS S7-200