omars

Member

To Whom It May Concern:

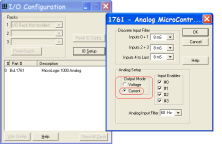

I am working with a MicroLogix 1000 analog I/O module and it is the first time I have had to program analog I/O with it. I have the discrete I/O working fine but need advice on how I would write a program to test each analog I/O channel. It has two voltage inputs from 0-10 VDC and two current inputs from 4-20 mA. If it wouldn't be asking for too much, I would appreciate if someone could send me a sample program to test my I/O. Thank you in advance. - Omar

I am working with a MicroLogix 1000 analog I/O module and it is the first time I have had to program analog I/O with it. I have the discrete I/O working fine but need advice on how I would write a program to test each analog I/O channel. It has two voltage inputs from 0-10 VDC and two current inputs from 4-20 mA. If it wouldn't be asking for too much, I would appreciate if someone could send me a sample program to test my I/O. Thank you in advance. - Omar