Hello All,

New at this and trying to tune a PID in Logix Designer.

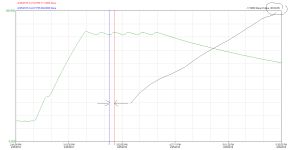

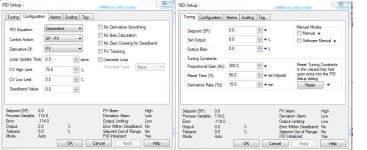

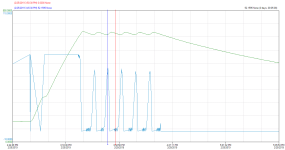

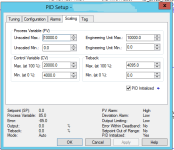

Basically we have some electric heaters heating up some platens and no matter what pid settings i try its always overshooting by 80 degrees roughly. I think its because the pid starts throttling back the output right when it hits the PV setpoint..which is too late since it takes time for the heat from the heaters to get to the thermocouple. Not sure what setting would be good to help the PID anticipate that lag. Any suggestions would be great

thanks

New at this and trying to tune a PID in Logix Designer.

Basically we have some electric heaters heating up some platens and no matter what pid settings i try its always overshooting by 80 degrees roughly. I think its because the pid starts throttling back the output right when it hits the PV setpoint..which is too late since it takes time for the heat from the heaters to get to the thermocouple. Not sure what setting would be good to help the PID anticipate that lag. Any suggestions would be great

thanks