That part has a 5000 Hz sample rate - looks ok for a RPI of 5ms

jrupp82 - have you used the trend functionality of RS logix 5000 ?

Set up a trend with angle, your timer and the trigger - watch what is happening - you should be able to see each 5 ms RPI step change , see how big each step is and when you are triggering SHOE analysis of the trend will assist you in working out what is happening

I have not opened your program yet but there are some timing things that may be needed / help

1) copy your angle into a local variable and use the local variable for testing - the value can change mid instruction

2) You are triggering an Event that then calls your SHOE TASK - why?

Have you thought about using a task that is attached to the RPI of the analog being updated - must be a very fast (ie small) bit of code

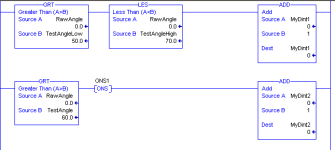

3) Change your "in window" logic - Think about using a wider window and when you exit that window test if you are on the trigger side of the wider window - if so then eject - you may need to set a latch if reverse is a possibility

The window logic is saying "have I just passed 130 deg in the forward direction" if so then run the "SHOE" task

4) what priority is the "SHOE" task (maybe I should just read the program but I am tired)

5) You may need to cause the output to turn on before it is required as you speed up (reaction time of the solenoids)

jrupp82 - have you used the trend functionality of RS logix 5000 ?

Set up a trend with angle, your timer and the trigger - watch what is happening - you should be able to see each 5 ms RPI step change , see how big each step is and when you are triggering SHOE analysis of the trend will assist you in working out what is happening

I have not opened your program yet but there are some timing things that may be needed / help

1) copy your angle into a local variable and use the local variable for testing - the value can change mid instruction

2) You are triggering an Event that then calls your SHOE TASK - why?

Have you thought about using a task that is attached to the RPI of the analog being updated - must be a very fast (ie small) bit of code

3) Change your "in window" logic - Think about using a wider window and when you exit that window test if you are on the trigger side of the wider window - if so then eject - you may need to set a latch if reverse is a possibility

The window logic is saying "have I just passed 130 deg in the forward direction" if so then run the "SHOE" task

4) what priority is the "SHOE" task (maybe I should just read the program but I am tired)

5) You may need to cause the output to turn on before it is required as you speed up (reaction time of the solenoids)

Last edited: