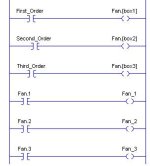

I have eight solenoid valves which works on six different pattern (pattern1 up to pattern6)based upon time .

Each pattern has its own timing for opening and closing of valves.

Now I have two modes which are Continuous mode and timed mode .

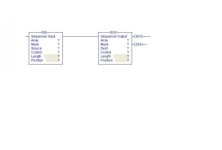

The user must specify to run the continuous wave program or the timed wave program. If the user selects the continuous program they must select one wave pattern to be able to start the wave. If the user selects the timed program, they will have to specify the “ON” time and the “OFF” time, then select which wave patterns to run. They can select multiple patterns in a sequence that will run every time the waves start.

There are 6 different wave types. I have attached the document.

View attachment sequenc.xls

Once the program parameters are set up the user can initiate the waves by pressing the start

button. Once the start is initiated the solenoid valves begin to operate by opening and closing.

As in the attached document using timers I can achieve all the pattern sequence but only one thing I don’t understand.

Operator will select any sequence of pattern like,

Pattern 2, pattern 4, pattern 1, pattern 6, pattern 3, pattern 5.

Each time he will select different pattern based upon which the patterns should execute.

If he selects one at a time I have no problem that sequence will work for “x” minutes then he has to select the next pattern .

But selecting the patterns all at once I don’t know how to make that work in ladder logic .

Please some Idea , how can I achieve the order of pattern ???????

Sequence of each pattern for opening and closing valves easy , but to arrange these pattern in order based upon operaters entry is what confussing me .

Please give me some suggestion .

I am using Rslogix 5000 .

should I have to assign any standard value and use compare option but each time he will enter a different order of pattern please . Please give me some idea .

Each pattern has its own timing for opening and closing of valves.

Now I have two modes which are Continuous mode and timed mode .

The user must specify to run the continuous wave program or the timed wave program. If the user selects the continuous program they must select one wave pattern to be able to start the wave. If the user selects the timed program, they will have to specify the “ON” time and the “OFF” time, then select which wave patterns to run. They can select multiple patterns in a sequence that will run every time the waves start.

There are 6 different wave types. I have attached the document.

View attachment sequenc.xls

Once the program parameters are set up the user can initiate the waves by pressing the start

button. Once the start is initiated the solenoid valves begin to operate by opening and closing.

As in the attached document using timers I can achieve all the pattern sequence but only one thing I don’t understand.

Operator will select any sequence of pattern like,

Pattern 2, pattern 4, pattern 1, pattern 6, pattern 3, pattern 5.

Each time he will select different pattern based upon which the patterns should execute.

If he selects one at a time I have no problem that sequence will work for “x” minutes then he has to select the next pattern .

But selecting the patterns all at once I don’t know how to make that work in ladder logic .

Please some Idea , how can I achieve the order of pattern ???????

Sequence of each pattern for opening and closing valves easy , but to arrange these pattern in order based upon operaters entry is what confussing me .

Please give me some suggestion .

I am using Rslogix 5000 .

should I have to assign any standard value and use compare option but each time he will enter a different order of pattern please . Please give me some idea .