Marcosbelgo

Member

Hi friends,

This is my first work with simatic and I am having some difficulties to comunicate S7 with HMI.

HMI: T5F-2 Beijer Electronics

S7 1200 1214C

I understood that to make this, I have to use T_CON. But, it is not clear for me.

Wich Is it nescessary blocks to estabilish communication, T_CON and T_SEND? wich parameters I have to set in these blocks? What is REQ????? What else I have to do in the TIA?

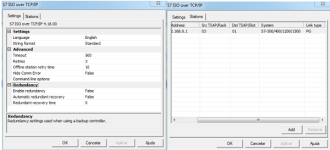

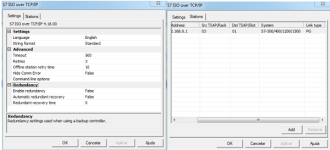

Bellow, I attached the screen configuration for HMI, what I put in src TSAP/rack dist/TSAP slot and link type (PG or OP)?

Thanks

Marcos

This is my first work with simatic and I am having some difficulties to comunicate S7 with HMI.

HMI: T5F-2 Beijer Electronics

S7 1200 1214C

I understood that to make this, I have to use T_CON. But, it is not clear for me.

Wich Is it nescessary blocks to estabilish communication, T_CON and T_SEND? wich parameters I have to set in these blocks? What is REQ????? What else I have to do in the TIA?

Bellow, I attached the screen configuration for HMI, what I put in src TSAP/rack dist/TSAP slot and link type (PG or OP)?

Thanks

Marcos