You probably aren't going to want to hear this but I don't think there is an easy way to do what you want to do given the current formatting. As you are seeing, the concept of individual data files is gone in the Logix processors. They way you would handle this kind of thing if you were designing it from the ground up would be as an array of UDTs.

So the basic jist of this is that data files N11 through N24 contain recipes. The recipe data file is selected by N10:11. Internal to a given recipe file there are separate data groupings related to a specific recipe item. These are separated in groups of 30 data locations. Internal to each recipe item there are multiple zones that are supported for that recipe item determined by the value of C5:7.

Given what you currently have to work with there isn't going to be an easy way to select the recipe number. Each recipe is in a separate 201-element data array right now. One way to attack this may be to use a COP to copy the contents of a specific "file" into a working array. For example, in the SLC program if recipe 1 is selected then file N11 would be the data file used. You could then use brute force to determine which "file" array is needed and copy it to your working array. After that, the array indexes into the working array would be the same values currently calculated as N10_21 through N10_26.

What I would probably do (if I weren't rewriting this from the ground up) would be create a separate 2-dimensional array with the major dimension being 25 and the minor dimension being 201. Then I would individually copy the separate "file" arrays (N11 thorugh N24) into the new array using the COP command. For example, something like:

COP(N11[0], DataArray[11,0], 201)

would copy the contents of N11 into the new data array at major index 11. Doing the dame thing to file N12 would be:

COP(N12[0], DataArray[12,0], 201)

This is a temporary copy that is only used to restructure your data. As soon as you have N11 through N24 into the new data array the COP isn't needed anymore.

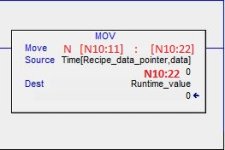

Once this is done, DataArray[N10_11, N10_22] will get you exactly the same thing as the old N[N10:11]:[N10:22] in the SLC.

As I said, there is a better way to do this but this is probably the quickest way to get you where you need to go. Also, once you are sure the recipe data is where you want it and correct, I would delete the N11 through N24 files just to avoid future confusion.

Keith