Hi everyone, I'm currently finding ways to create variable that can be read & write between 2 Beckhoff controllers.

Target to be achieved:

1) PLC A has a variable named "Temp_Setpoint"

2) PLC B should be able to read "Temp_Setpoint" value from PLC A

3) PLC B should be able to update the value of "Temp_Setpoint" in PLC A

One way to achieve this is by using Beckhoff EAP (EtherCAT Automation Protocol).

The problem with EAP is you can only link a variable one time only, either to an EAP Publisher or an EAP Subscriber.

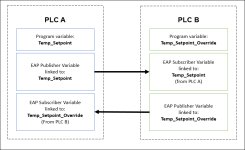

So in order to achieve the target, we have to create a clone variable in PLC B, as shown in this attached picture:

Imagine this, if we have 100 variables that need to be read/write between 2 PLCs, we need to create another 100 clone variables, which is very inefficient in my opinion.

Is there any better way to do this?

Any advice is welcome! Hope to hear your sharing and thoughts!

Thank you!

Target to be achieved:

1) PLC A has a variable named "Temp_Setpoint"

2) PLC B should be able to read "Temp_Setpoint" value from PLC A

3) PLC B should be able to update the value of "Temp_Setpoint" in PLC A

One way to achieve this is by using Beckhoff EAP (EtherCAT Automation Protocol).

The problem with EAP is you can only link a variable one time only, either to an EAP Publisher or an EAP Subscriber.

So in order to achieve the target, we have to create a clone variable in PLC B, as shown in this attached picture:

Imagine this, if we have 100 variables that need to be read/write between 2 PLCs, we need to create another 100 clone variables, which is very inefficient in my opinion.

Is there any better way to do this?

Any advice is welcome! Hope to hear your sharing and thoughts!

Thank you!