Sorry, not really PLC's. I have been going around and around trying to get a solid answer to my question and not finding anything that really makes it clear to me.

I am working with a single phase 480V in 5kVA transformer with a grounded secondary providing 240/120V. ACME TB253014S

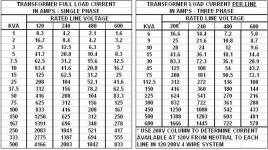

How would one go about properly sizing the secondary conductors?

PS: A previous designer has this as 14 on the primary, #6 for L1/2 and #10 for the center (Neutral/GND). it seems a bit much in my opinion for the loads

I am working with a single phase 480V in 5kVA transformer with a grounded secondary providing 240/120V. ACME TB253014S

How would one go about properly sizing the secondary conductors?

PS: A previous designer has this as 14 on the primary, #6 for L1/2 and #10 for the center (Neutral/GND). it seems a bit much in my opinion for the loads