defcon.klaxon

Lifetime Supporting Member

Hi all,

For as long as I've been programming Allen Bradley PLCs, I've pretty much stuck to ladder logic but I am interested in what function block diagrams might be able to offer.

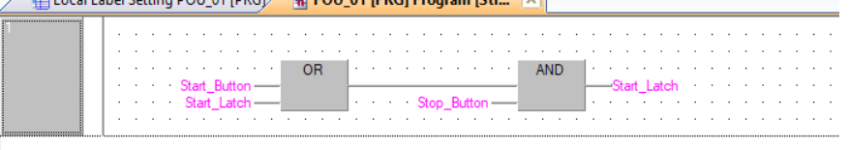

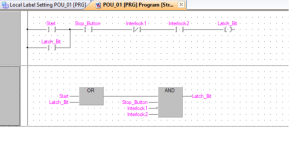

One thing I've been trying to figure out is how one would seal in coils in FBD versus LD and after some google searching, I haven't found anything that has been very helpful. What I've found does seem to show the idea with AND blocks but it seems somewhat convoluted and more "busy" visually than ladder diagrams so it seems like it's not worth the effort. Thus I'd like to ask y'all if this is possible and if so, how would you go about it and maybe I'm missing something that would make FBD sealing in as simple as LD.

Thanks!

For as long as I've been programming Allen Bradley PLCs, I've pretty much stuck to ladder logic but I am interested in what function block diagrams might be able to offer.

One thing I've been trying to figure out is how one would seal in coils in FBD versus LD and after some google searching, I haven't found anything that has been very helpful. What I've found does seem to show the idea with AND blocks but it seems somewhat convoluted and more "busy" visually than ladder diagrams so it seems like it's not worth the effort. Thus I'd like to ask y'all if this is possible and if so, how would you go about it and maybe I'm missing something that would make FBD sealing in as simple as LD.

Thanks!

Last edited: