lunenburger

Member

I have 3 control panels made by an OEM, they are all identical and have a Siemens S7-1200 PLC with a Siemens CB-1241 Modbus card talking to 2 Vacon 20 VFD's.

The PLC program in the working panels is password protected so no help there.

We have to make changes to the process and the OEM is gone, so I purchased the exact plc and modbus card and wrote a new program.

All I have done is pop off the terminal strips from the OEM PLC and installed my new PLC so there have been no wiring changes at all.

I can control both VFD's over Modbus and everything looks fine, but after a couple minutes the MB Master instruction starts getting

16#80C8 error (timeout error) and

16#80E2 error (frame error)

After a couple of hours of running, the Vacon VFD's will fault out.

I can pop the old OEM plc back in and there are no errors (I can get online with the OEM PLC and see their MB Master tag values)

So that means there are no wiring or noise issues (I believe)

This is my first Siemen's PLC program, I have been programming AB for almost 20 years, so there is something wrong with my Siemens program but I can't figure it out.

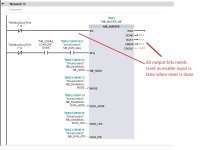

I have rewritten the program three times, once using multiple instances of the same MB Master block and a hz counter to fire messages in sequence.

Rewrote that one to use the MB Master done bit to move to the next step..

Rewrote again to use a single instance of the MB Master instruction and used the step function to move in the different values.

All programs are getting the same errors

I have triple checked the Modbus settings in drive and PLC and they are:

9.6 kbps

no parity

8 bits per character

1 stop bit

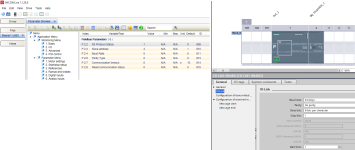

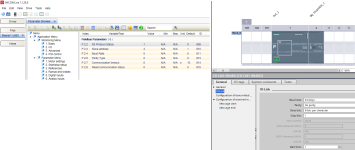

I have attached a pic of Modbus settings from both PLC and VFD

Also attached a link to PLC program on OneDrive:

https://1drv.ms/u/s!AmzzeJcgGAJomAThZRSm3va8I9r3?e=dCTAYj

Thanks in advance for any advice...

The PLC program in the working panels is password protected so no help there.

We have to make changes to the process and the OEM is gone, so I purchased the exact plc and modbus card and wrote a new program.

All I have done is pop off the terminal strips from the OEM PLC and installed my new PLC so there have been no wiring changes at all.

I can control both VFD's over Modbus and everything looks fine, but after a couple minutes the MB Master instruction starts getting

16#80C8 error (timeout error) and

16#80E2 error (frame error)

After a couple of hours of running, the Vacon VFD's will fault out.

I can pop the old OEM plc back in and there are no errors (I can get online with the OEM PLC and see their MB Master tag values)

So that means there are no wiring or noise issues (I believe)

This is my first Siemen's PLC program, I have been programming AB for almost 20 years, so there is something wrong with my Siemens program but I can't figure it out.

I have rewritten the program three times, once using multiple instances of the same MB Master block and a hz counter to fire messages in sequence.

Rewrote that one to use the MB Master done bit to move to the next step..

Rewrote again to use a single instance of the MB Master instruction and used the step function to move in the different values.

All programs are getting the same errors

I have triple checked the Modbus settings in drive and PLC and they are:

9.6 kbps

no parity

8 bits per character

1 stop bit

I have attached a pic of Modbus settings from both PLC and VFD

Also attached a link to PLC program on OneDrive:

https://1drv.ms/u/s!AmzzeJcgGAJomAThZRSm3va8I9r3?e=dCTAYj

Thanks in advance for any advice...