While I appreciate all the responses and apparent interest here, I think everyone is way overthinking this and this discussion has gotten in to the weeds a bit. There are a lot of requests for additional info to answer questions I never asked, while the ones I did ask remain mostly unaddressed.

First, some clarifications, mostly repeated info at this point, since I know there will be a slew of unrelated questions otherwise:

1. The system was professionally designed by a firm with a lot of experience in the field, so I am sure everything is designed and sized correctly, and if it isn't it's not my problem. I do not know the specs of the pumps, other than that they are 150HP and they are all the same. I have requested this info several weeks ago, but the contracting company is not very responsive, so I am proceeding anyways. It's really not that big of a deal. I am assuming with fair certainty centrifugal pumps and a 20% minimum pump speed. Also, the site is under construction and nearing completion, so no change requests will be made, certainly not by me.

2. The process control description is very basic, but as mentioned asks for PID control of the 4 pumps which will be sequentially enabled when they are in their start/stop windows, which are ascending by level. All 4 pumps will have the same target level SP they are trying to maintain. I have mentioned some values in an earlier post, if anyone cares. That's all the spec says. However, the specs directly call for PID control and the specs are gospel, so that is what I am contractually obligated to deliver. As @Saffa mentioned, I can simply set I or D values to 0 if needed, but this is really a tuning issue, which will be handled at startup and I don't anticipate any difficulty with it.

Now, if I could redirect everyone back to the original questions, I would appreciate it.

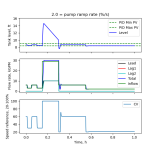

1. Is it worthwhile to use a PIDE block here over a regular PID block, considering I will need to spend a little time familiarizing myself with it and what useful options should I look for (since there are so many)? I am leaning towards using the PIDE just on the basis of rate change limits and bumpless handover, but that brings my next question.

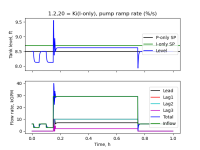

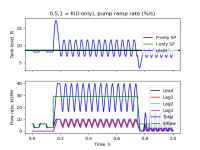

2. What are recommendations between using the PIDE's built in rate of change limiter vs using an RLIM external to it? Any practical difference? My initial plan is to use both, with the internal limiter set to be a little faster for more responsive control and using an extra RLIM on pump start that brings it up to speed a little slower before bypassing it.

3. From a control strategy overview, any high-level recommendations on setting up the control? My plan is a single PIDE block (potentially tuned to PI), when adding pumps ramp them up at a fixed rate until their speed matches the PIDE CV speed (which will be falling due to the new pump) and then hand them over to the PIDE control which will be scaled to the number of running pumps.