MaxK

Member

Yes it's essentially correct.

CVn above will be equal to CVn-1.

i.e. If Kp=1, Ki=0, Kd=0, and for example SP = 8.5 SP(n-1)=PV

I suppose CV(n-1)=0, so CV

Yes it's essentially correct.

CVn above will be equal to CVn-1.

i.e. If Kp=1, Ki=0, Kd=0, and for example SP = 8.5 SP(n-1)=PV=PV(n-1) = 10

Undetermined unless you set it to some value almost like a bias. The incremental form of PID doesn't work unless there is an integrator gain.Possibly off topic

I Please to excuse me for such noob question:

PIDE formula:

CV= CV(n-1) + Kp * delta_E + Ki*E*delta_t + Kd*(E

- 2*E(n-1) + E(n-2))/delta_t

is it correct?

If Kp=1, Ki=0, Kd=0, and for example SP = 8.5 PV=PV(n-1) = 10

What is the value of CV?

Now, if I could redirect everyone back to the original questions, I would appreciate it.

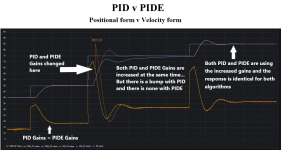

1. Is it worthwhile to use a PIDE block here over a regular PID block, considering I will need to spend a little time familiarizing myself with it and what useful options should I look for (since there are so many)? I am leaning towards using the PIDE just on the basis of rate change limits and bumpless handover, but that brings my next question.

2. What are recommendations between using the PIDE's built in rate of change limiter vs using an RLIM external to it? Any practical difference? My initial plan is to use both, with the internal limiter set to be a little faster for more responsive control and using an extra RLIM on pump start that brings it up to speed a little slower before bypassing it.

3. From a control strategy overview, any high-level recommendations on setting up the control? My plan is a single PIDE block (potentially tuned to PI), when adding pumps ramp them up at a fixed rate until their speed matches the PIDE CV speed (which will be falling due to the new pump) and then hand them over to the PIDE control which will be scaled to the number of running pumps.

Undetermined unless you set it to some value almost like a bias. The incremental form of PID doesn't work unless there is an integrator gain.

Undetermined unless you set it to some value almost like a bias. The incremental form of PID doesn't work unless there is an integrator gain.

My plan is a single PIDE block (potentially tuned to PI), when adding pumps ramp them up at a fixed rate until their speed matches the PIDE CV speed (which will be falling due to the new pump)

...I'll post them here and you can go wild.

Not quite; CVn-1 is, in effect, both bias and accumulated I-term (Σ Ki E Δt).

The incremental form is mathematically the same as the absolute form, and it works fine without an integrator gain. There may be roundoff in the sixth decimal place.

It requires cv(0) be set to a good value initially.

All it does is add complications.

Actually, as long as Δt is small enough, it is quite provable.P.S. I consider the stability of the function CVn = CVn-1 + KP * ΔEn (taking into account the conditions of real systems) mathematically unprovable. i.e. using PIDE P-only is unsafe