I've seen a lot of strange happenings in Rockwell Software. Some of the time I can hammer away at the issue until I solve the problem. The rest of the time, I rely on the experience of the great people that make up this forum. This is one of those times.

Our press has been displaying an alarm state on its beacon, but no message appears on the HMI to indicate which alarm is tripped. I started digging through the program to see which one of the 80 possible alarms is causing the trouble. As it turns out, the beacon is tripped by a bit in the program that is true when any of the 5 integer files for the alarms is not equal to 0.

This is where it gets strange... None of the preceding logic in the rung is true, and yet the output bit is true. The press is not in a shutdown condition, which makes sense because there is no actual alarm. But how can an output be true if the inputs are all false? There are two XICs, two XIOs, and one OTE attached to this bit, so it isn't getting activated elsewhere in the program. There are no MOV instructions or anything like that associated with this bit at all, and under "usage" there is no indication of FW.

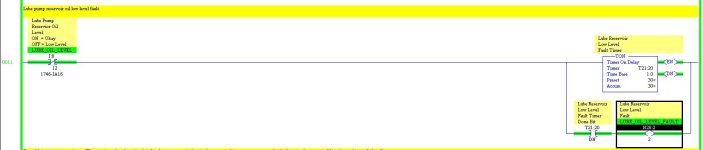

This is on a 1747-L541C 5/04 processor OS401 Series C FRN 3-8, running RSLogix 500 V9 CPR 9. I have attached an image of the offending rung. The test bit was just inserted to make sure I wasn't going insane and seeing something that wasn't there.

Our press has been displaying an alarm state on its beacon, but no message appears on the HMI to indicate which alarm is tripped. I started digging through the program to see which one of the 80 possible alarms is causing the trouble. As it turns out, the beacon is tripped by a bit in the program that is true when any of the 5 integer files for the alarms is not equal to 0.

This is where it gets strange... None of the preceding logic in the rung is true, and yet the output bit is true. The press is not in a shutdown condition, which makes sense because there is no actual alarm. But how can an output be true if the inputs are all false? There are two XICs, two XIOs, and one OTE attached to this bit, so it isn't getting activated elsewhere in the program. There are no MOV instructions or anything like that associated with this bit at all, and under "usage" there is no indication of FW.

This is on a 1747-L541C 5/04 processor OS401 Series C FRN 3-8, running RSLogix 500 V9 CPR 9. I have attached an image of the offending rung. The test bit was just inserted to make sure I wasn't going insane and seeing something that wasn't there.