IdealDan take a look to this : https://industrial.softing.com/uploads/softing_downloads/OPCS004E_201110_OPC_Server_01.pdf

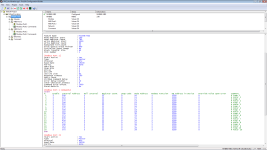

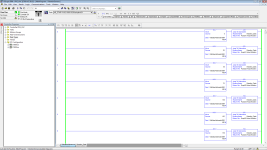

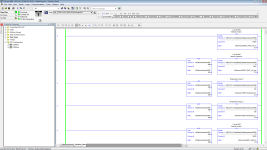

An OPC server that can read the data from a variety of PLC and protocols, and present all the data as a organized Node Tree as an OPC server does.

For sure it will be easier to configure than to program a central PLC to scan the data of the different PLCs

An OPC server that can read the data from a variety of PLC and protocols, and present all the data as a organized Node Tree as an OPC server does.

For sure it will be easier to configure than to program a central PLC to scan the data of the different PLCs