JaxGTO

Member

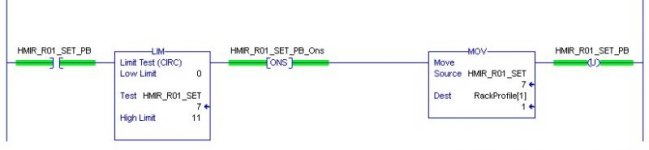

OK Compact Logix V21

I have a rung in a continious task where the button and the one shot got stuck.

Basic rung:

|--] [----[ONS]---MOV (A to B)-----(U)---|

The ] [ is PB, [ONS] is PBONS and the (U) is PB

I have a Wonderware that sets bit PB from a button. They were complaining that the data from A to B was not getting moved when they pressed the button.

Went online and both the PB and PBONS bits were on. I can't think of a single possibility how they could both be on at the same time. Neither is used in the program anywhere else and bot are bool type. I thought maybe if the PB was set when the PLC was in program mode, but even then first scan would fire the ONS and reset the PB.

Any thoughts? Jack.

I have a rung in a continious task where the button and the one shot got stuck.

Basic rung:

|--] [----[ONS]---MOV (A to B)-----(U)---|

The ] [ is PB, [ONS] is PBONS and the (U) is PB

I have a Wonderware that sets bit PB from a button. They were complaining that the data from A to B was not getting moved when they pressed the button.

Went online and both the PB and PBONS bits were on. I can't think of a single possibility how they could both be on at the same time. Neither is used in the program anywhere else and bot are bool type. I thought maybe if the PB was set when the PLC was in program mode, but even then first scan would fire the ONS and reset the PB.

Any thoughts? Jack.