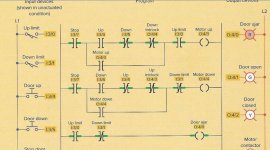

Hello guys, I am now taking a PLC class. In my textbook we have a diagram for a garage door opener. This is using AB SLC 500. The attached page is straight from the textbook. It appears to be showing that the door is currently ajar. Rung 3 is completely true and the red door ajar pilot light is on. What I don't understand is... in rung 1 the "up" LS at address I:3/0 has an XIC instruction that appears to be true. I don't see how the LS can be closed if the door isn't fully opened. Rung 3 shows the same thing.

The description at the top says it uses a normally open-held closed up limit switch. What is holding it closed if the door isn't fully opened? Is it a mistake in the book or, a mistake in my head?

The description at the top says it uses a normally open-held closed up limit switch. What is holding it closed if the door isn't fully opened? Is it a mistake in the book or, a mistake in my head?