There are some things that seem to be a little confusing first of all it is assumed this is the cooling recirculation pump is that correct ?.

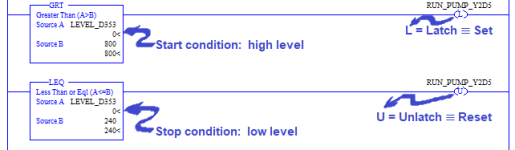

If so, why wait until the level rises to the 800mm level to re-start the recirc?.

assumptions:

Providing the level is above min low level i.e. 240mm why not run the pump, why wait until it is above 800mm, surely providing there is a minimum level it is ok to run the cooling ?.

The filling of the tank could be auto or manual does not matter, the normal procedure would be to re-fill the tank either man or auto when the level gets close to the lower level not wait until below re-circulation level, this means the cooling recirc does not have to stop ?.

As I have said before, we had a number of systems like this that fed cooling water to sealing heads, originally, these were not supplied by the sealer machine suppliers, these were completely manual top up, often the heads would over heat & alarm on flow not detected, we automated the top up so that providing the level was above minimum the recirculation would run, when the level fell to something like 10% above minimum the top up would operate, there was a manual override, this worked in the same way as the logic posted.

I really do not see why you need to hold off the recirc until the tank is full.

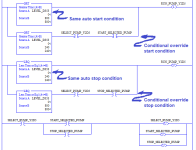

If it was me, but the system actually or was desirable to also have manual run/stop during an auto run then this is what I would do.

Instead of having loads of operator interventions before production i.e. selecting & starting systems just have one auto start button, this would reset any manual selections & providing all the criteria have been met run the complete system in auto, any manual requirement should it be required could be selected & would stay in place until either a complete auto re-start or de-selected by the operator (this bit would depend on operational requirements).

all the filling/recirculation would be monitored & should a problem occur i.e. failed to fill within a certain time etc. would alarm to inform the operator & in the event that the problem was not rectified within certain times or parameters (safety of personnel or damage to equipment) halt the process.

Unfortunately, operators get used to the way it used to work & seem resistant to change, had this on a system, the company wanted more auto control on a batching system to alleviate the problems that occurred due to operator mistakes & sometimes their unwillingness to keep to production schedules, we modified the system but the operators complained, this was more to do with the operators believing they would be either reduced in numbers or made to do extra tasks. Ironically, a similar system we put into another plant some miles away where the "NEW" operators were sent to the other plant to learn the basics of the system asked why the existing system had so many operator interventions & why the operators were so resistant to a simpler & easier system to operate, the answer was "it is the way we have always done it".

If so, why wait until the level rises to the 800mm level to re-start the recirc?.

assumptions:

Providing the level is above min low level i.e. 240mm why not run the pump, why wait until it is above 800mm, surely providing there is a minimum level it is ok to run the cooling ?.

The filling of the tank could be auto or manual does not matter, the normal procedure would be to re-fill the tank either man or auto when the level gets close to the lower level not wait until below re-circulation level, this means the cooling recirc does not have to stop ?.

As I have said before, we had a number of systems like this that fed cooling water to sealing heads, originally, these were not supplied by the sealer machine suppliers, these were completely manual top up, often the heads would over heat & alarm on flow not detected, we automated the top up so that providing the level was above minimum the recirculation would run, when the level fell to something like 10% above minimum the top up would operate, there was a manual override, this worked in the same way as the logic posted.

I really do not see why you need to hold off the recirc until the tank is full.

If it was me, but the system actually or was desirable to also have manual run/stop during an auto run then this is what I would do.

Instead of having loads of operator interventions before production i.e. selecting & starting systems just have one auto start button, this would reset any manual selections & providing all the criteria have been met run the complete system in auto, any manual requirement should it be required could be selected & would stay in place until either a complete auto re-start or de-selected by the operator (this bit would depend on operational requirements).

all the filling/recirculation would be monitored & should a problem occur i.e. failed to fill within a certain time etc. would alarm to inform the operator & in the event that the problem was not rectified within certain times or parameters (safety of personnel or damage to equipment) halt the process.

Unfortunately, operators get used to the way it used to work & seem resistant to change, had this on a system, the company wanted more auto control on a batching system to alleviate the problems that occurred due to operator mistakes & sometimes their unwillingness to keep to production schedules, we modified the system but the operators complained, this was more to do with the operators believing they would be either reduced in numbers or made to do extra tasks. Ironically, a similar system we put into another plant some miles away where the "NEW" operators were sent to the other plant to learn the basics of the system asked why the existing system had so many operator interventions & why the operators were so resistant to a simpler & easier system to operate, the answer was "it is the way we have always done it".