Mas01

Member

We have a water scavenge pump. The pump is switched on/off by the operator entering high & low setpoints. Operator has brought to my attention that a low setpoint of zero could be entered (causing damage to the pump), or a high setpoint of e.g. 999mm ( which would cause damage to the test equipment).

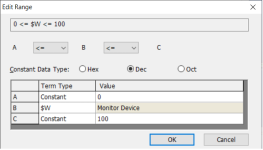

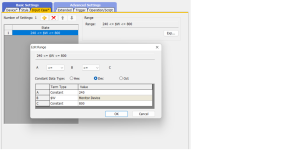

Is there a way to limit this value to restrict the inputs to "safe" values, e.g. 250mm (low) and say 800mm (high)?

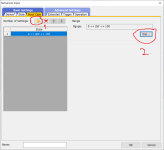

Wasn't sure if this needs doing in the code eg do a limit check, set a M-bit, then use the M-bit to display a message on the HMI...or do the check in GT designer on the relevant 'numerical input' dialogue.

Is there a way to limit this value to restrict the inputs to "safe" values, e.g. 250mm (low) and say 800mm (high)?

Wasn't sure if this needs doing in the code eg do a limit check, set a M-bit, then use the M-bit to display a message on the HMI...or do the check in GT designer on the relevant 'numerical input' dialogue.