Mas01

Member

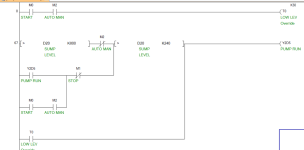

That is why I did the top rung as one of the alternatives, this allowed to start/stop the pump manually without the need for an Auto/Man selector so gave him both options, it still works in auto so will stop when reaches low level but does not need to be at high level to start it manually, as for not being able to start the pump at high level is ridiculous as it would auto start anyway if not in manual. if it was above high level surely you would want to be able to start the pump to lower the level.

You are unlikely to get information about the whole process as it appears that either the original supplier or the company he works for are reluctant to divulge too much.

I prefer the top rung idea, to be honest, but operator wants a manual/auto selector. Also I like your idea of a manual/auto toggle in which the associated text changes from "auto" to "manual" because , for me, space is limited on the HMI screen....I was going to have a toggle button with a lamp next to it which takes up more space.

Last edited: