It is my understanding that an LED is considered a simple device, making its use fairly simple in an IS application.

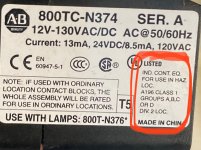

However I am running into a problem with this AB PL. Customer went digging for an IS cert, which is not needed and ended up on the phone with AB. According to AB it is not considered a simple device, I am still waiting for additional information from the customer on why.

Anyone have any insight?

However I am running into a problem with this AB PL. Customer went digging for an IS cert, which is not needed and ended up on the phone with AB. According to AB it is not considered a simple device, I am still waiting for additional information from the customer on why.

Anyone have any insight?