sporkins

Member

Hello all. I'm new to the world of PLCs and I have a few questions. I'm sure they have all been asked before, and I apologize for the repeat, but searching has not been bringing me the answers I'm looking for.

I'm building an animatronic figure, with 8 analog axes of motion (0-10VDC signals). Typically I would use a Gilderfluke animation control system, which works great for animation, but doesn't have any sort of safety interlock or manual override options. I need to keep the Gilderfluke system in place, but would need to add a system that can monitor the outputs, and also act as a safety/manual override system.

First, what sort of costs are usually associated with PLCs? After doing preliminary searches, I think something like an A-B Micrologix 1200R will meet my needs, but I'm not positive.

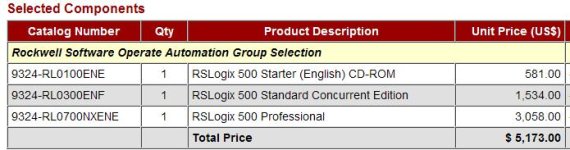

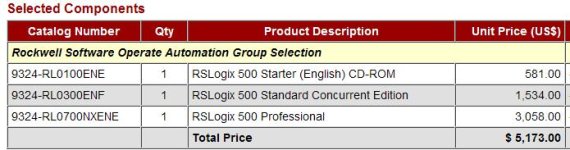

So if that were my PLC, what else would I need, and what sorts of prices would I be looking at? Obviously, the PLC, I/O modules, and some sort of operator interface. What else would need to be factored in? Are there any first time costs such as specialized software that need to be considered?

I know there will be a lot of man-hours associated with my programming/setup/learning curve as well. What would be a realistic timeline for learning this sort of system? While I am new to PLCs, I'm not a complete newbie when it comes to programming or electronics.

What are some vendors for PLCs and components? Whats the typical availability? What other options are out there that are roughly equivalent to the Micrologix?

Thanks in advance for your help.

I'm building an animatronic figure, with 8 analog axes of motion (0-10VDC signals). Typically I would use a Gilderfluke animation control system, which works great for animation, but doesn't have any sort of safety interlock or manual override options. I need to keep the Gilderfluke system in place, but would need to add a system that can monitor the outputs, and also act as a safety/manual override system.

First, what sort of costs are usually associated with PLCs? After doing preliminary searches, I think something like an A-B Micrologix 1200R will meet my needs, but I'm not positive.

So if that were my PLC, what else would I need, and what sorts of prices would I be looking at? Obviously, the PLC, I/O modules, and some sort of operator interface. What else would need to be factored in? Are there any first time costs such as specialized software that need to be considered?

I know there will be a lot of man-hours associated with my programming/setup/learning curve as well. What would be a realistic timeline for learning this sort of system? While I am new to PLCs, I'm not a complete newbie when it comes to programming or electronics.

What are some vendors for PLCs and components? Whats the typical availability? What other options are out there that are roughly equivalent to the Micrologix?

Thanks in advance for your help.