Wow... this is a first for me.

A piece of code shows up on PLCtalk that I am 99% sure I know the author of.

Is the system called SoftSpeed or SoftTorque? I recognize the DB numbers and naming... the name of the program gives away the other clues.

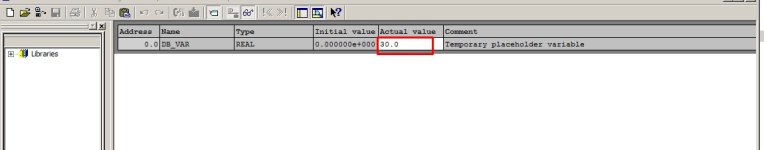

No this is not soft torque, i am studying the original program and using some blocks from there to simulate one by one by copy and paste from there to understand how the program works. my program is very simple but the original program has some function blocks which i can use in mine

Last edited: