can u tell me if i have an analog input what output parameter i can use to configure pulse....

Yes, THIS is the crux of the problem. As parky mentioned earlier, using the pulsed signal directly from the meter is the easiest/simplest method. You will need to dig into the documentation for that meter to determine if a pulsed output is available and how to program/wire the signal. You will also want to make sure there is adequate time for the PLC to see the pulse as it transitions between on/off so that ALL pulses are counted.

If you must use the flow rate signal, then you will need to add programming in the Logix to generate that pulse internally. Even though there meter pulse examples in this and other forums, I STRONGLY suggest you figure out on paper the steps to accomplish this BEFORE diving into programming. That step is where you learn fundamental skills that will make your job as a controls engineer/programmer MUCH less stressful forevermore!

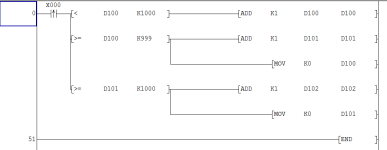

Let's break this down: You need to create a pulse for a certain volume (1 scf, 100 scf, etc.) but you are only given a flow rate (scfm).

Step 1 is to covert into a volume. You need to know the scan time between calculations in order to do this conversion - that's why a periodic task was advised earlier.

Step 2 is to add the converted volume to an accumulated volume value, then create a pulse once the accumulated volume reaches a certain value.

Step 3 As the pulse is created, the accumulated volume needs to decrease by the certain value specified above and keep counting. The pulse bit is what goes into your totalizer input.

Hopefully this is enough to get you started. Hey, we've all had that feeling of being overwhelmed and facing impending doom. Working things out on paper first has helped me as well as countless others.

If you really are crunched for time, you may need outside help as suggested above. Whether you're in Hartford, CT or some other Hartford, it's always a good idea to develop a relationship with your local distributor.