Gene Bond

Member

As mentioned, there are many levels of drives, and many levels of torque accuracy.

Closed Loop Vector would be the tightest, but far more accurate than required for this application.

ABB's 800 series are good. Control Techniques' M700 is even better (higher resolution and faster update times). But again, more than needed.

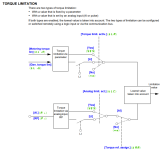

The CT M200 in RFC (Rotor Flux Control) is more than adequate. Just leave AI1 pointed to speed Reference, and set AI2 to Motoring Torque Limit (4.005). Works like a charm. 10 turn pots give good enough resolution. The built-in PLC can be used with input from limit switches and pushbuttons to automate the rest of the functions...

Closed Loop Vector would be the tightest, but far more accurate than required for this application.

ABB's 800 series are good. Control Techniques' M700 is even better (higher resolution and faster update times). But again, more than needed.

The CT M200 in RFC (Rotor Flux Control) is more than adequate. Just leave AI1 pointed to speed Reference, and set AI2 to Motoring Torque Limit (4.005). Works like a charm. 10 turn pots give good enough resolution. The built-in PLC can be used with input from limit switches and pushbuttons to automate the rest of the functions...