Problem with modification

Hi Guys,

This is a follow-up on the status of the Pin Installation Machine, and a question about a modification that I just made to it.

Recently my customer figured out a way to drill the hole for the pin on the CNC, and asked me to modify my machine for feeding and pressing in the pin only. Obviously, they could have done it by simply removing the drill bit from the self-feed drill, but they wanted me to "optimize" the machine for fastest cycle time.

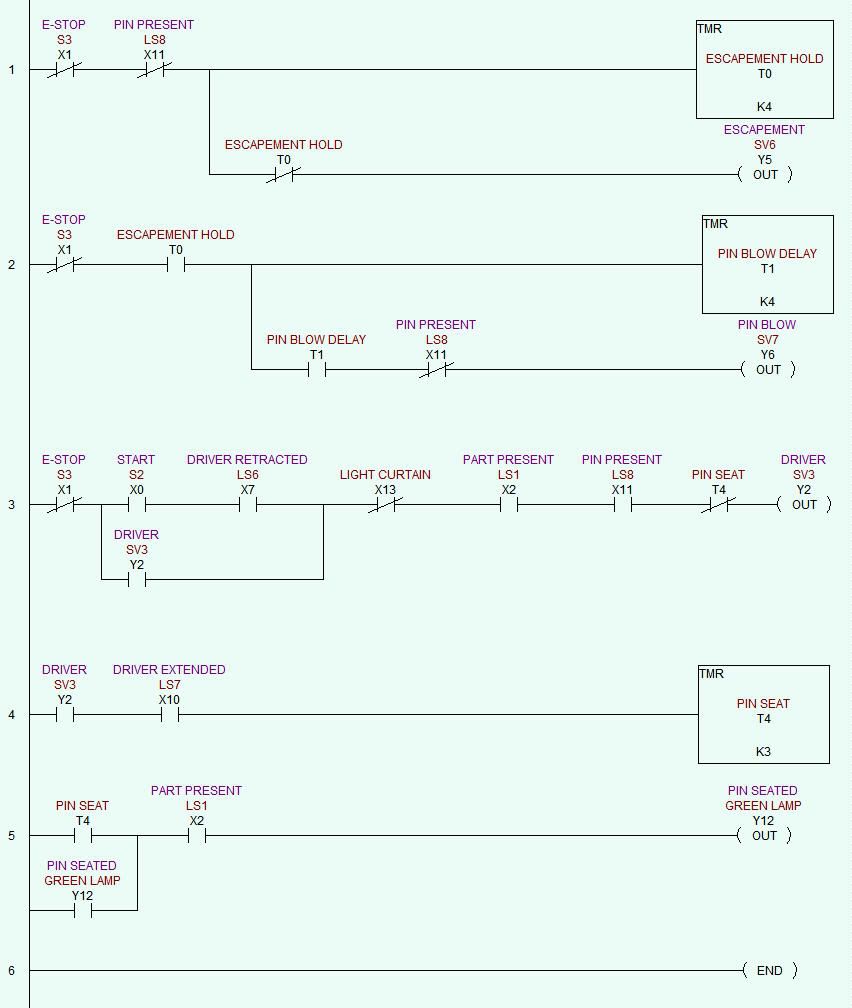

So, I made some mechanical modifications to the machine, and greatly simplified the PLC program. The sequence of operation now reads as follows:

1) With the machine powered up, the operator pulls out the STOP button, and presses the RESET button, activating the MCR.

2) If there is no pin in the nosepiece (X11), the escapement cylinder (Y5) is energized for .4 seconds (T0).

3) After another .4 second delay (T1), the Pin Blow valve (Y6) is energized until the pin arrives at the nosepiece (X11).

4) The operator places a part in the fixture, and presses START (X0).

5) If the part is detected in the fixture (X2), and there is a pin present in the nosepiece (X11), the driver cylinder is energized (Y2), pushing the pin into the hole.

6) Once the driver is extended (X10) for .3 seconds (T4), the driver is retracted, and a green lamp (Y12) is illuminated.

7) The operator removes the finished part from the fixture, and the lamp (Y2) goes off.

Here is the program I came up with:

This program works well, and the customer is very pleased with the 4-5 second cycle time. But there is a glitch in the program that I am unable to figure out. Whenever the control system is powered up with no pin in the nosepiece, the pin-feed sequence does not work. The Pin Blow valve (Y6) is energized, and just stays on, as though the Escapement step is bypassed.

If the driver (Y2) is then manually cycled once, the pin-feed sequence works properly from then on.

This is not a huge problem, since it only happened the first time I powered up the system (and the nosepiece was not "primed" with a pin), and after that only when they inadvertantly let the bowl run dry. But I feel like it's something really simple, and I'd like to fix it.

Anyone have an idea?

Paula