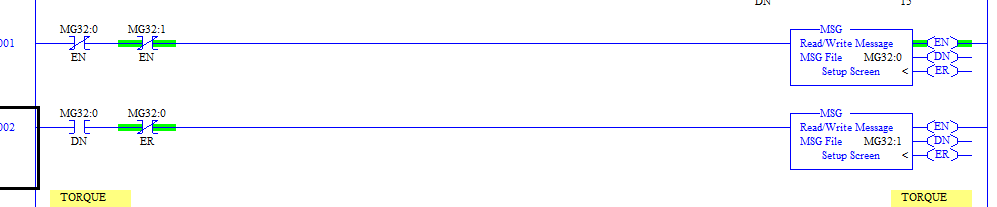

I have a ML 1400 Reading messages from 12 other PLC's.I have it set up so if the first message from each PLC gives an ER it will latch a bit and unlatch if that message gets a DN. I use these bits to signal the machine is powered down and PLC is off and I also use it to disabled any remaining messages from that PLC so I can skip over them, It works fine when most machines (PLC's) are powered up, if a few are powered down they show up on my excel sheet. My question is I noticed when I get to more than half the machines off (weekend)

It slows the system down enough that some machines on start to drop in and out, I see the TO bit toggling in the MSG file. All my messages are set at 33 seconds on the TO bit which I guess is default.

Any suggestions or does anyone have a different way of determining if target device is active,

It slows the system down enough that some machines on start to drop in and out, I see the TO bit toggling in the MSG file. All my messages are set at 33 seconds on the TO bit which I guess is default.

Any suggestions or does anyone have a different way of determining if target device is active,