dmargineau

Lifetime Supporting Member

Yowww, dmargineau, you just got burned

Just to add that Mitsubishi drives are the same.

It seems that my point did not go through...Trying again...

The provisions of external power supply are not there for one to use a straight PLC output to control a self powered third party device; it will work as such, however, it is not a safe, efficient and functionally sound integration. The separation between Control and Controlled is a fundamental principle of controls theory.

THEY MAKE RELAY OUTPUTS FOR THAT PURPOSE!.

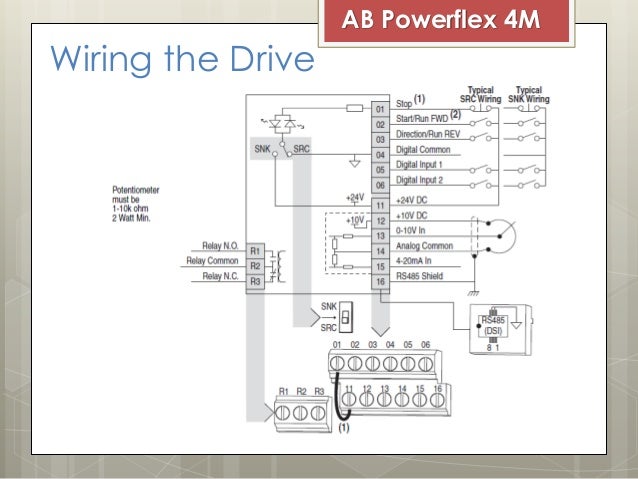

The OP asked about connecting the DI circuitry of a VFD to some timer device transistor output;...You need an Interposing Relay was my answer...That's the way it's been done since the inception of electrical controls...Rigging up and making it work without considering of all the caveats is amateurish at best...My $ 0.02...