jonrya91

Member

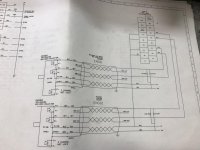

Here is my setup:

AB compactlogix PLC

1769HSC card

Automation direct 1024 incremental encoder

AB panelview 1500

104:1 gearbox (I've verified this is correct)

This is a simple mechanical arrangement of a motor and gearbox turning a caster wheel.

106,496 pulses per rev. represents one turn of the caster wheel. (104*1024)

Here is my problem:

If I mark the caster wheel with a reference to locate one turn, my display shows a complete turn that is roughly 10-15 degrees behind where it should be. Each turn gets more and more out of time.

I've ruled out the encoder being bad (replaced with new), the encoder slipping and the caster slipping.

I've had to increase my full rotation encoder count to roughly 118,600 in order for the machine to limp by.

Does anyone have any ideas?

AB compactlogix PLC

1769HSC card

Automation direct 1024 incremental encoder

AB panelview 1500

104:1 gearbox (I've verified this is correct)

This is a simple mechanical arrangement of a motor and gearbox turning a caster wheel.

106,496 pulses per rev. represents one turn of the caster wheel. (104*1024)

Here is my problem:

If I mark the caster wheel with a reference to locate one turn, my display shows a complete turn that is roughly 10-15 degrees behind where it should be. Each turn gets more and more out of time.

I've ruled out the encoder being bad (replaced with new), the encoder slipping and the caster slipping.

I've had to increase my full rotation encoder count to roughly 118,600 in order for the machine to limp by.

Does anyone have any ideas?