Ron Beaufort

Lifetime Supporting Member

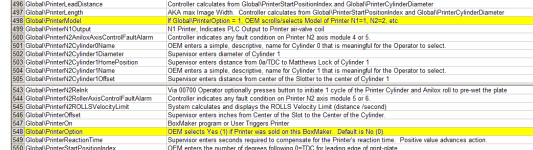

the zip file that you sent me has some "interesting" CSV files included ...

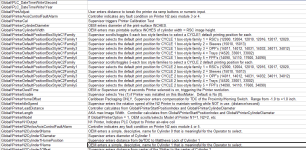

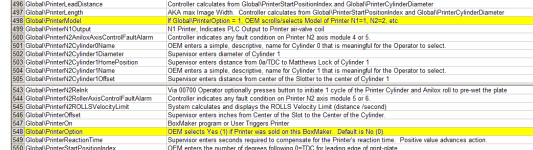

here's a screen shot from the one named Development-Tags201308051834.csv ...

the "OPTION" tag in the file you sent is set for 1 ... so ...

based on this - it "LOOKS LIKE" the OEM sold the customer a Printer with the machinery - and selected a printer model N2 ... what model printer is actually installed? ... can you tell by a nametag, etc. ???

just a thought ... maybe the printer actually is a model 2 - and maybe your problem with the machinery lies somewhere else? ...

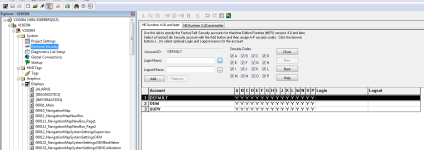

going further ... assuming that it is SAFE to experiment on this system - you might try this little trick ... IF "something" (like the HMI) is writing into the location Global\PrinterModel - then you might try just renaming the name of that tag as a temporary TEST ... for example: something like Global\PrinterModelTemp ... this is (usually) easy to do in the Edit section of the Controller Tags listing - and the change SHOULD "ripple" throughout all of the rest of the program code ... that means that the rest of the code IN THE PLC should keep on working normally - but any changes written into the tag from an OUTSIDE device would fail due to the "broken" link ...

so ...

IF (big IF) something actually is writing into the tag - it would USUALLY be linked to the tag by the name of the tag ... and with the name of the tag now changed - the link would be "broken" and whatever value you manually type into the tag's location should be left alone ... this is an old "debugging" trick that sometimes comes in useful when trying to isolate "disturbances" to various tag values ...

again - we can't tell from here whether it would be SAFE to try this on your machinery - but I offer it as another straw at which you might want to grasp ...

.

here's a screen shot from the one named Development-Tags201308051834.csv ...

the "OPTION" tag in the file you sent is set for 1 ... so ...

based on this - it "LOOKS LIKE" the OEM sold the customer a Printer with the machinery - and selected a printer model N2 ... what model printer is actually installed? ... can you tell by a nametag, etc. ???

just a thought ... maybe the printer actually is a model 2 - and maybe your problem with the machinery lies somewhere else? ...

going further ... assuming that it is SAFE to experiment on this system - you might try this little trick ... IF "something" (like the HMI) is writing into the location Global\PrinterModel - then you might try just renaming the name of that tag as a temporary TEST ... for example: something like Global\PrinterModelTemp ... this is (usually) easy to do in the Edit section of the Controller Tags listing - and the change SHOULD "ripple" throughout all of the rest of the program code ... that means that the rest of the code IN THE PLC should keep on working normally - but any changes written into the tag from an OUTSIDE device would fail due to the "broken" link ...

so ...

IF (big IF) something actually is writing into the tag - it would USUALLY be linked to the tag by the name of the tag ... and with the name of the tag now changed - the link would be "broken" and whatever value you manually type into the tag's location should be left alone ... this is an old "debugging" trick that sometimes comes in useful when trying to isolate "disturbances" to various tag values ...

again - we can't tell from here whether it would be SAFE to try this on your machinery - but I offer it as another straw at which you might want to grasp ...

.

Last edited: