phuz

Member

System: steam cooker with a volume of about 900 cubic feet. 2" steam valve. RTD for temperature input.

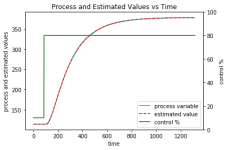

From a cold start, valve wide open, it takes about 8 minutes to reach temp, but when it gets there, it holds pretty well. The issue I am having is when they introduce product, the temperature will dip, and per government regulation, we cannot drop more than 2 degrees. The valve is certainly able to keep up, but I am noticing the loop (PIDE) is not using as much output as it needs to.

The temperature is dropping about 1.8 degrees, which is dangerously low to the low cut-out. At steady state prior to introducing product, the CV is about 20%. When product is introduced, I only see the loop ramp up to about 35% all while the temp is continuing to dip. I started with PID parameters of 20 / 1.5 / 0 and even increased the PI to 35 / 2 but I am still not getting as big of a reaction as I would expect.

I have a couple other quick-acting loops that are almost perfect, but I am struggling with this slower one. I'd appreciate any insight from the PID experts.

From a cold start, valve wide open, it takes about 8 minutes to reach temp, but when it gets there, it holds pretty well. The issue I am having is when they introduce product, the temperature will dip, and per government regulation, we cannot drop more than 2 degrees. The valve is certainly able to keep up, but I am noticing the loop (PIDE) is not using as much output as it needs to.

The temperature is dropping about 1.8 degrees, which is dangerously low to the low cut-out. At steady state prior to introducing product, the CV is about 20%. When product is introduced, I only see the loop ramp up to about 35% all while the temp is continuing to dip. I started with PID parameters of 20 / 1.5 / 0 and even increased the PI to 35 / 2 but I am still not getting as big of a reaction as I would expect.

I have a couple other quick-acting loops that are almost perfect, but I am struggling with this slower one. I'd appreciate any insight from the PID experts.