Bering C Sparky

Lifetime Supporting Member

Hello all,

Long time no see.

Just got back on the ship in Dutch Harbor. The moment I walk on my counterpart tells me we have a major fault on the only "Allen Bradley" PLC we have. (They use AD on here)

The Micrologix 1400 is in our incinerator, the program is proprietary and password protected.

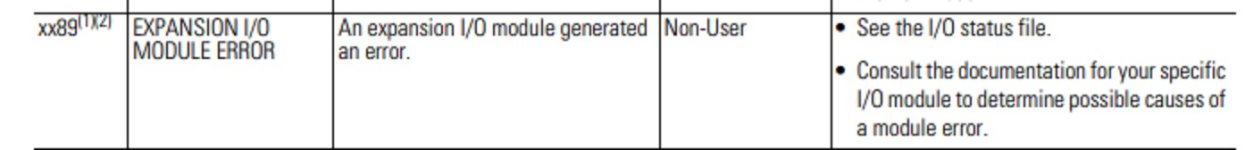

I was able to get the fault code from the onboard LCD (0389h) but not having a lot of luck finding what this fault code actually is.

My counterpart said he looked it up and found it had to do with expansion module #3. Can't say where he got that information as I have not been able to find it on the internet. (#3 expansion module is a 1762-IF2OF2)

We have no AB software onboard, its been 4 years since I touched a AB PLC and I cannot remember my password to the AB information data base online. (Lucky I was able to remember the password to this forum)

Could someone please tell me.....

What is this fault code?

Can it be cleared without the use of RSLogix 500 software?

I have tried the following with no joy.

Powering the PLC on and off.

Switching from Run to Program and back on the LCD

Changing out expansion module #3 then repeating 1 & 2 above.

Starting to think I am going to have call around and borrow a laptop with AB software from another vessel, but not even sure anymore if that will do me any good, since I know for a fact the program is password protected.

I remember trying to make some changes in to this PLC 4 years ago when I first got on this vessel and could not due it being locked down.

I do have a brand new PLC that just arrived from the vendor and is supposedly preloaded with the correct program.

But I do not believe a new PLC is actually going to be the fix to this problem, so I would like to exhaust any other options before trying to swap out the entire 1400 controller.

Not a great moment when a 1400 has me dead in the water from a fault, but without the software I think I may have gone as far as I am able for the moment.

Will keep hunting around online to see if I can find this fault code and will check back to see if anyone replies to this post.

Thanks in advance for any assistance.

(I see my PM box is 90% full as well....guess that's bound to happen when you have not checked it for a long period of time, will look through it after I get this problem sorted and we are underway)

Long time no see.

Just got back on the ship in Dutch Harbor. The moment I walk on my counterpart tells me we have a major fault on the only "Allen Bradley" PLC we have. (They use AD on here)

The Micrologix 1400 is in our incinerator, the program is proprietary and password protected.

I was able to get the fault code from the onboard LCD (0389h) but not having a lot of luck finding what this fault code actually is.

My counterpart said he looked it up and found it had to do with expansion module #3. Can't say where he got that information as I have not been able to find it on the internet. (#3 expansion module is a 1762-IF2OF2)

We have no AB software onboard, its been 4 years since I touched a AB PLC and I cannot remember my password to the AB information data base online. (Lucky I was able to remember the password to this forum)

Could someone please tell me.....

What is this fault code?

Can it be cleared without the use of RSLogix 500 software?

I have tried the following with no joy.

Powering the PLC on and off.

Switching from Run to Program and back on the LCD

Changing out expansion module #3 then repeating 1 & 2 above.

Starting to think I am going to have call around and borrow a laptop with AB software from another vessel, but not even sure anymore if that will do me any good, since I know for a fact the program is password protected.

I remember trying to make some changes in to this PLC 4 years ago when I first got on this vessel and could not due it being locked down.

I do have a brand new PLC that just arrived from the vendor and is supposedly preloaded with the correct program.

But I do not believe a new PLC is actually going to be the fix to this problem, so I would like to exhaust any other options before trying to swap out the entire 1400 controller.

Not a great moment when a 1400 has me dead in the water from a fault, but without the software I think I may have gone as far as I am able for the moment.

Will keep hunting around online to see if I can find this fault code and will check back to see if anyone replies to this post.

Thanks in advance for any assistance.

(I see my PM box is 90% full as well....guess that's bound to happen when you have not checked it for a long period of time, will look through it after I get this problem sorted and we are underway)