Nhrafan26

Member

I know this has been brought up before and I have read through many posts and tried many different things before asking...

I am using a ML1400 Ser B.

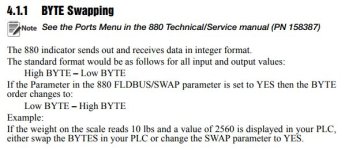

The application I have running sends a Modbus message to a scale head to find out the weight. The message results are stored in N12:60 for 4 elements.

Then taking N12:63 and moving it to N7:3, leaving the rest behind. Somehow this seems to get around the 32767 limitation and it reads instead in Hex format and does not fault out with an overflow error.

However I want to take 3 of these readings, combine them and put them into another register (N15:30) so I can send this information to a server piece.

No matter how I try to do this it will not work or be accurate.

I have tried the following:

ADD N16:3 and N16:4 result into F8:1

ADD F8:1 and N16:19 result into F8:2

MOV F8:2 into L22:0

CPW L22:0 into N21:0 (for testing purposes) length of 2.

Result I get is N21:0 is not the number or even close and N21:1 is 1

I'm sure there's plenty more information needed but I thought you could have a look and see if we can get the ball rolling on how to solve this.

Issue is it is for a scale that reads up to 65,000 lbs. I wand to combine 3 of them and report the total number.

I am using a ML1400 Ser B.

The application I have running sends a Modbus message to a scale head to find out the weight. The message results are stored in N12:60 for 4 elements.

Then taking N12:63 and moving it to N7:3, leaving the rest behind. Somehow this seems to get around the 32767 limitation and it reads instead in Hex format and does not fault out with an overflow error.

However I want to take 3 of these readings, combine them and put them into another register (N15:30) so I can send this information to a server piece.

No matter how I try to do this it will not work or be accurate.

I have tried the following:

ADD N16:3 and N16:4 result into F8:1

ADD F8:1 and N16:19 result into F8:2

MOV F8:2 into L22:0

CPW L22:0 into N21:0 (for testing purposes) length of 2.

Result I get is N21:0 is not the number or even close and N21:1 is 1

I'm sure there's plenty more information needed but I thought you could have a look and see if we can get the ball rolling on how to solve this.

Issue is it is for a scale that reads up to 65,000 lbs. I wand to combine 3 of them and report the total number.