You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

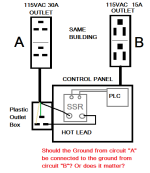

Is grounding from A to B required in the attched Pic? this grounding matter?

- Thread starter skyfox

- Start date

rdrast

Lifetime Supporting Member

If you have a grounded outlet, it MUST be tied to ground.

If you have a grounded outlet, it MUST be tied to ground.

Theoretically, both A and "B" would have the same ground refrence. What I was asking was to find out if I needed to ground (tie the ground wire from "A" to the ground wire from circuit "B" inside the control panel? For instance, say somebody unplugged "Circuit "B" power cord and left circuit "A" power cord plugged in. Considering a hot wire is traveling in to the control panel from Circuit "A" (to the SSR) and circuit "B" or the control panel no longer has a ground reference, couldn't this scenario present an unsafe condition inside the control cabinet?

I agree with rdrast - It must be grounded. (For safety's sake.)

In my opinion . . . If the B circuit is from an isolated ground panel - then the

A circuit should be grounded to the same isolated ground as the B circuit.

It is still grounded - but grounded in a manner to keep 'ground loops' from

happening.

(I have a system that runs off an isolated ground panel. A jack-leg electrician

grounded my system to the building ground - giving my system two ground points.

In two days it corrupted data in two computers. I got a real electrician in there

to find and re-isolate things. Been good ever since.)

Poet.

In my opinion . . . If the B circuit is from an isolated ground panel - then the

A circuit should be grounded to the same isolated ground as the B circuit.

It is still grounded - but grounded in a manner to keep 'ground loops' from

happening.

(I have a system that runs off an isolated ground panel. A jack-leg electrician

grounded my system to the building ground - giving my system two ground points.

In two days it corrupted data in two computers. I got a real electrician in there

to find and re-isolate things. Been good ever since.)

Poet.

alive15

Member

Assuming the outlets are side by side, wouldn't the grounds already be jumpered together anyways?

Why two voltage sources?

Why are you designing a control panel with two separate voltage sources?

If you do two sources, please see NEC70 about CODE required marking.

If this for premises wiring then NFPA70 is the Enforced CODE requirements.

If this for industrial machine control then NFPA79 the expected consensus STANDARDS suggestion guidelines.

If unsure, 30 amps of 120 is either a fire risk, or lethal to humans, ask your local electrician.

Regards

Is it required or can it be kept isolated from the control panel circuit?

Why are you designing a control panel with two separate voltage sources?

If you do two sources, please see NEC70 about CODE required marking.

If this for premises wiring then NFPA70 is the Enforced CODE requirements.

If this for industrial machine control then NFPA79 the expected consensus STANDARDS suggestion guidelines.

If unsure, 30 amps of 120 is either a fire risk, or lethal to humans, ask your local electrician.

Regards

Your ground needs to be referenced to earth. If both grounds are earth, and you tie both grounds to earth, then both grounds are referenced to the same potential. They do not have to be tied directly together, but they both need to be tied to the same reference point, which is likely earth, but not always. Just almost always. Determining if you are that exception is on you.

If you aren't certain of this, consult with a local qualified person.

If you aren't certain of this, consult with a local qualified person.

Why are you designing a control panel with two separate voltage sources?

Well, I am not actually designing this but being asked to come up with a way to toggle the remote power source on/off using the existing control Panel. I guess in a way it is sort of designing. That is why I asked the question about using an SSR to accomplish this. I realize I have to bring the hot wire from the secondary source in to the control cabinet, because that is where I initially envisioned having the SSR installed. Which means, now there are two sources of power inside the control cabinet as some of you have stated. What if the SSR was located inside a metal outlet box, totally away from and unattached to the control panel as far as 115VAC is concerned, but only connected by the low voltage DC control signal wires from the Control Panel?

Does that make a difference?

Again, thanks for everyone's help and feedback. Much appreciated.

alive15

Member

What's wrong with having two separate sources in a panel? Is it dangerous? I would say if all wires are labeled properly, then what's the issue with it?

If both grounds are earth, and you tie both grounds to earth, then both grounds are referenced to the same potential.

Actually there is a potential voltage difference between 2 earth ground points.

I was involved with a serviceperson commissioning a new feeder for an automatic stamping press we had bought. The servo controller that should have fed a precise length of steel kept fluctuating. He couldn't figure it out and called in Rockwell service.

As soon as they (not 'he') looked at the setup, they stated that the machine was grounded to the ground rod for the press, in front of the machine. But, the feeder control panel, on the back of the machine, had its own ground rod that the servo controller was tied to.

The measured voltage (Ecm I think) between the 2 earth grounds was almost 8 volts - more than enough to send 5 volt ghost signals from the motor encoder to the servo controller. They had us run a bunch of ground wires from each point to every other point and the problem went away.

OkiePC

Lifetime Supporting Member

What's wrong with having two separate sources in a panel? Is it dangerous? I would say if all wires are labeled properly, then what's the issue with it?

There are rules for properly identifying this situation to someone who might be unaware that more than one disconnecting means is required to make it safe. Nothing wrong with having multiple power sources as long as the panel is properly marked.

Little bit of the topic... But I think that SSR is not ideal solution for this scenario, it would be better to use standard contactor. The contactor is classical potential free contact that doesn't require minimum load because it is mechanical contact. Also you can "cut" both phase and neutral.

Actually there is a potential voltage difference between 2 earth ground points.

As soon as they (not 'he') looked at the setup, they stated that the machine was grounded to the ground rod for the press, in front of the machine. But, the feeder control panel, on the back of the machine, had its own ground rod that the servo controller was tied to.

Well, if you install two grounding rods 'x' distance apart, you can easily have different potential across the earth. There is a reason that building systems tend to have an equipotential grounding electrode. The idea being that you bring all earths down to the same potential and to provide a common reference as well as a low impedance path to earth for any abnormal system conditions. It makes me wonder why there were two ground rods on the machine. Did you end up just leaving one off or running a new wire to the other end of the machine?

Similar Topics

Hi all,

I'm connecting several 4-20mA sensors together in parallel (only one shown below) The enclosure is ABS plastic with metal backplate

DAQ...

- Replies

- 5

- Views

- 263

I have Rhino 120 to 24 dc power supply and it has 2 Positive and 2 negative terminals on the DC side but no ground terminal. Should I connect one...

- Replies

- 9

- Views

- 432

Hi,

Our customer has bought a machine a CNC wood cutting machine. It states that it need a seperate 16mm2 EMV"ground" in addition to our 5G16mm2...

- Replies

- 2

- Views

- 598

I have a Beckhoff PLC with many AI modules. Most devices are loop powered using the same +24 VDC power as the Beckhoff Bus Coupler and all is...

- Replies

- 5

- Views

- 664

I was once asked a question in a job interview. "Do you ground both ends of a shield?"

I answered: "You only ground one end".

Apparently that was...

- Replies

- 12

- Views

- 4,931