renatusigm

Member

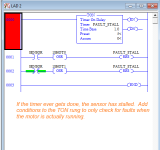

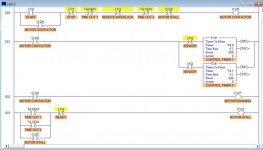

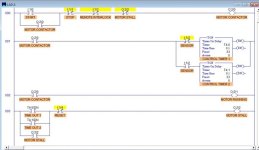

Hello guys, I am Renatus. This is my first time to join and participate in this forum. I am a student and am pursuing my project for additional overheating protection of Induction motor using PLC. The system will incorporate the proximity sensor which will be used to detect the rotational motion of the motor, the signal (voltage pulses) from the proximity sensor will be the input to the PLC and that signal I will be programmed such that the Timer On Delay will be activate to switch the power supply Off when the signal into the PLC is not detected within the 30sec when the motor stalls (Blocked by external matters) or running at low speed. I have planned to use Micrologix 1000 PLC.

My difficult is How will I make the wiring of the PLC inputs with start,stop push button and proximity sensor and the output of the PLC with the motor starter?

please guys I really need your help on how to do wiring in PLC because I am still a beginner in PLC field. thank you.

My difficult is How will I make the wiring of the PLC inputs with start,stop push button and proximity sensor and the output of the PLC with the motor starter?

please guys I really need your help on how to do wiring in PLC because I am still a beginner in PLC field. thank you.