taknevs

Member

hi all,

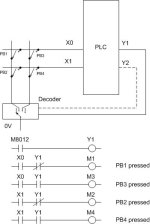

i am writing a ladder logic in which i need to distinguish between single push and double push of a Pushbutton (similar to single click and double click using a mouse). i am using mitsubishi FX1N PLC and GX developer ver. 7 software.

A single push of the pushbutton (input X0) should perform one operation (say activate output Y0) and double push of the push button should perform another operation (activate output Y1). The PLC will look for single or double push within a certain timeperiod say (1 second) That's why I have used a 1 second timer in my program.

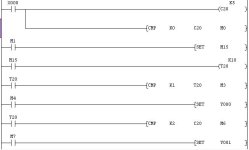

This is the program:

LD X0

OUT C20 K5

CMP K0 C20 M0

LD M1

SET M15

LD M15

OUT T20 K10

LD T20

CMP K1 T20 M3

LD M4

SET Y0

LD T20

CMP K2 C20 M6

LD M7

SET Y1

END

I am sorry I could not give the picture of the ladder logic i dont know how to get it from GX developer software. If anyone have any suggestions, pls let me know.

NOTE: I tried to achive the same result using AB micrologix1200 and I could easily get the single push/double push variation.

thanks in advance

taknevs

i am writing a ladder logic in which i need to distinguish between single push and double push of a Pushbutton (similar to single click and double click using a mouse). i am using mitsubishi FX1N PLC and GX developer ver. 7 software.

A single push of the pushbutton (input X0) should perform one operation (say activate output Y0) and double push of the push button should perform another operation (activate output Y1). The PLC will look for single or double push within a certain timeperiod say (1 second) That's why I have used a 1 second timer in my program.

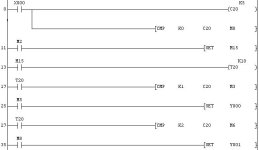

This is the program:

LD X0

OUT C20 K5

CMP K0 C20 M0

LD M1

SET M15

LD M15

OUT T20 K10

LD T20

CMP K1 T20 M3

LD M4

SET Y0

LD T20

CMP K2 C20 M6

LD M7

SET Y1

END

I am sorry I could not give the picture of the ladder logic i dont know how to get it from GX developer software. If anyone have any suggestions, pls let me know.

NOTE: I tried to achive the same result using AB micrologix1200 and I could easily get the single push/double push variation.

thanks in advance

taknevs