Hello!

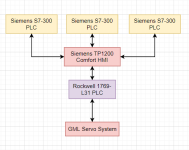

We are trying to do an upgrade on a clients system. It was built about 20 years ago and the current communication setup is Siemens PLC (CPU314C-2 DP) -> Citect Scada 5.42 -> 1394 GMC Turbo which was programmed with GML Commander. The servo system gets its information from Citect system and the PLC doesn't communicate directly to the servo system.

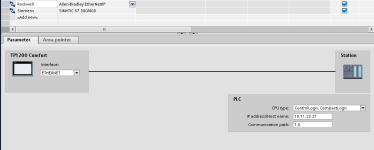

Now we are trying to eliminate the Citect Scada system from the equation and add a Siemens TP1200Comfort and the PLC must communicate directly to the servo system.

What i could gather from the Citect system is that it sends/receives about 20 INT data types most of them are recipe parameters with the 1349 GMC Turbo

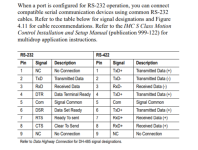

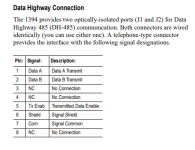

It seems that the communication is currently being done with the servo system through DH485 in the J1 port.

What i am trying to figure out how to get the PLC and servo system talking the same language without messing with the 1394 GMC Turbo and GML Commander too much.

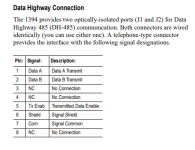

I found the DH485 pinout for the servo system from the manual (attached to the post) So i guess that should be the servo side cable pinout?

Could someone please give me some clues or direction what would be the move to get the Siemens PLC and Rockwell Servo system communicating with each other?

We are trying to do an upgrade on a clients system. It was built about 20 years ago and the current communication setup is Siemens PLC (CPU314C-2 DP) -> Citect Scada 5.42 -> 1394 GMC Turbo which was programmed with GML Commander. The servo system gets its information from Citect system and the PLC doesn't communicate directly to the servo system.

Now we are trying to eliminate the Citect Scada system from the equation and add a Siemens TP1200Comfort and the PLC must communicate directly to the servo system.

What i could gather from the Citect system is that it sends/receives about 20 INT data types most of them are recipe parameters with the 1349 GMC Turbo

It seems that the communication is currently being done with the servo system through DH485 in the J1 port.

What i am trying to figure out how to get the PLC and servo system talking the same language without messing with the 1394 GMC Turbo and GML Commander too much.

I found the DH485 pinout for the servo system from the manual (attached to the post) So i guess that should be the servo side cable pinout?

Could someone please give me some clues or direction what would be the move to get the Siemens PLC and Rockwell Servo system communicating with each other?