You have your 10 variables. When all is finished move these to 10 new variables that is the tags to be logged. These are to be logged "on change". So every time you want to log you move your values to the logging tags and the values are logged. If you have mode 1 and 2 then create 10 variables for mode 1 and one for mode 2. Then move the actual values you want to log to the mode you want to log it to.

Focus your control of the logging to how you move your readings to mode 1 or 2.

Hello all. I am doing a similar application as was described in this thread.

I want to log a pressing motion where I have the following data to be logged:

So I log two force values on every 0.1mm for 2 mm. So I have 20 logs per fore transducer.

I move the values to a DB where I have 3 arrays (of 20 real's). 1 array for the servo position, 1 array for force transducer 1, 1 array for force transducer 2.

I want to log this tot the CSV with a KTP700 comfort panel.

I configured the datalog like so:

Storage location - Data records: -Path: - logging method

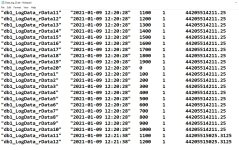

CSV file(ASCII) - 5000000 - /Storage card SD... - Circural log

In the logging tags I inputed all the tags from the DB.

Press position-Press-Force1-PressForce2

I tried this but it's a mess, I have way more logs that should be... Is it because when the axis is moving and the DB starts to fill with the data, the HMI makes all the excess logs?

I am thinking of moving the DB(where values are being stored while the pressing is being done to another DB(when the pressing is done) try to log these tags?

I hope you know what I mean...

Cheers all.