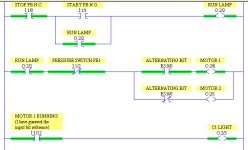

Part 2 – Alternating Compressors when Loading is Light

In this part, each compressor is to take its turn bringing the storage tank pressure back up to the

selected pressure setting. Pneumatic/Electric switch PE1 will continue to be utilized for this

purpose and the settings will remain the same as those used in the previous exercise.

selected pressure setting. Pneumatic/Electric switch PE1 will continue to be utilized for this

purpose and the settings will remain the same as those used in the previous exercise.

Allow the user to start and stop the air system using the appropriate panel mounted switches, and

ensure that the "Run" lamp is illuminated whenever the system is enabled. Lamp "C1" should be

illuminated only when compressor #1 is actually running.

Prior to testing your program, adjust the system's discharge flow rate to 50% as shown. This

setting should prove to be low enough that a single compressor will then be able to supply the

needs of this particular pneumatic system.

Once you have created your program, download it to the PLC and test out its operation. When

the start button is pressed, the Compressor should start and begin to build up pressure within the

storage tank. Once the pressure reaches 120PSI, the compressor should stop, and remain idle

until the pressure in the storage tank drops below 110PSI.ensure that the "Run" lamp is illuminated whenever the system is enabled. Lamp "C1" should be

illuminated only when compressor #1 is actually running.

Prior to testing your program, adjust the system's discharge flow rate to 50% as shown. This

setting should prove to be low enough that a single compressor will then be able to supply the

needs of this particular pneumatic system.

Once you have created your program, download it to the PLC and test out its operation. When

the start button is pressed, the Compressor should start and begin to build up pressure within the

storage tank. Once the pressure reaches 120PSI, the compressor should stop, and remain idle

i got part one to work where one motor will go on and off during the PSI cant get the dual motors to alternate can someone help please thank you!