Hi folks,

I'll try to keep this as short as possible, also I don't expect anyone to go through troubleshooting the whole issue on here as there's so too many things it could be. I only provided an overview of the ongoing issues so that if something in the screenshots provided below pops out to someone and the story behind it backs that up then I'll be happy having narrowed down the issue. All I really want is the screenshots to be viewed and any potential issues flagged. I only recently graduated so network issues wouldn't be my strong point

(BTW we are using InTouch 10.1 with AB 1756 ControlLogix PLC's)

So, we recently commissioned a second line in one of our plants and during commissioning we had comms issues; after updating the SCADA for example it would take anywhere between a few seconds to a few hours for the data to start populating, temperatures, pressures etc. So we added another subnet to reduce the load on the original and that seemed to work OK at the time.

Since then though if we need to update the SCADA it may or may not communicate immediately afterwards, the time still varies. I watched the Log file in System Management Console last time this happened and errors of either "invalid item 'tagname' not defined in processor", "unknown object name" or "Device connection attempt to xxx timed out, socket closed" kept popping up. Under the configuration tree where you can view the tag list, they are usually green if everything is OK, red if there's issues or nothing at all if you're not connected, the tags would show red for a few seconds, then disappear altogether, come back red after a few seconds and repeat. After a few hours of monitoring, shutting down, reopening or reactivating the server in various combinations it became clear something needed to be changed so I tried increasing the max CIP connections and it worked, no idea why as it was working fine before the update (typical!) but it did. The time before that it happened on a different station so it doesn't seem to be one station in particular, and I did not need to increase the CIP connections on either of the other two for them to work which leads me to believe it couldn't have been the update either.

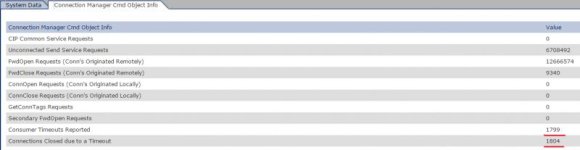

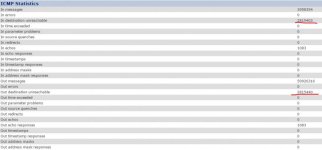

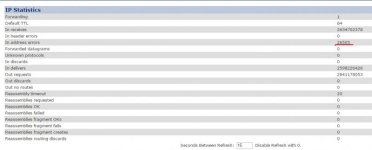

Anyway today I was having a look at the PLCs web server and noticed a few things that may point us in the right direction, I just don't know heaps about it so if there is anything glaringly obvious to someone more in the know I can at least pass this information on and maybe we can get someone in to have a look.

I took 4 screenshots of potential problems (from the PLC on the original line, the newer line has less IO so going to start here) and highlighted what stood out to me.

Thanks in advance for your help

PS. it's taken me so long to write this concisely that the day is almost over so apologies for any delay in replying over the weeked/bank holiday!

I'll try to keep this as short as possible, also I don't expect anyone to go through troubleshooting the whole issue on here as there's so too many things it could be. I only provided an overview of the ongoing issues so that if something in the screenshots provided below pops out to someone and the story behind it backs that up then I'll be happy having narrowed down the issue. All I really want is the screenshots to be viewed and any potential issues flagged. I only recently graduated so network issues wouldn't be my strong point

(BTW we are using InTouch 10.1 with AB 1756 ControlLogix PLC's)

So, we recently commissioned a second line in one of our plants and during commissioning we had comms issues; after updating the SCADA for example it would take anywhere between a few seconds to a few hours for the data to start populating, temperatures, pressures etc. So we added another subnet to reduce the load on the original and that seemed to work OK at the time.

Since then though if we need to update the SCADA it may or may not communicate immediately afterwards, the time still varies. I watched the Log file in System Management Console last time this happened and errors of either "invalid item 'tagname' not defined in processor", "unknown object name" or "Device connection attempt to xxx timed out, socket closed" kept popping up. Under the configuration tree where you can view the tag list, they are usually green if everything is OK, red if there's issues or nothing at all if you're not connected, the tags would show red for a few seconds, then disappear altogether, come back red after a few seconds and repeat. After a few hours of monitoring, shutting down, reopening or reactivating the server in various combinations it became clear something needed to be changed so I tried increasing the max CIP connections and it worked, no idea why as it was working fine before the update (typical!) but it did. The time before that it happened on a different station so it doesn't seem to be one station in particular, and I did not need to increase the CIP connections on either of the other two for them to work which leads me to believe it couldn't have been the update either.

Anyway today I was having a look at the PLCs web server and noticed a few things that may point us in the right direction, I just don't know heaps about it so if there is anything glaringly obvious to someone more in the know I can at least pass this information on and maybe we can get someone in to have a look.

I took 4 screenshots of potential problems (from the PLC on the original line, the newer line has less IO so going to start here) and highlighted what stood out to me.

Thanks in advance for your help

PS. it's taken me so long to write this concisely that the day is almost over so apologies for any delay in replying over the weeked/bank holiday!

Last edited: