Mas01

Member

Hi, On a previous thread I asked about how to connect a float switch to a PLC.

http://www.plctalk.net/qanda/showthread.php?t=126829

As I'm a complete novice and feeling completely out my depth, once I've connected the switch, in general terms, what are the next things I need to do?

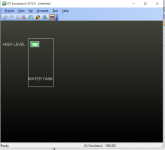

Ultimately, I want to monitor the water level in a tank by monitoring the switch (closed when water is at the level of a switch) on a screen (done in GX designer?). And also I imagine I need to update the PLC software to recognise the new data (switch position).

Please can someone help me with a general list of things I need to do once the switch is connected to the PLC, and which software to use at each stage. I know we have GX developer and GX designer and something called GOT but not sure what that is for.

Thanks

http://www.plctalk.net/qanda/showthread.php?t=126829

As I'm a complete novice and feeling completely out my depth, once I've connected the switch, in general terms, what are the next things I need to do?

Ultimately, I want to monitor the water level in a tank by monitoring the switch (closed when water is at the level of a switch) on a screen (done in GX designer?). And also I imagine I need to update the PLC software to recognise the new data (switch position).

Please can someone help me with a general list of things I need to do once the switch is connected to the PLC, and which software to use at each stage. I know we have GX developer and GX designer and something called GOT but not sure what that is for.

Thanks

Last edited: