ranasingheum

Member

Hello,

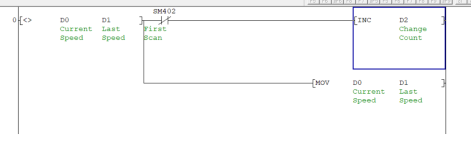

I'm trying to trigger an output when an integer number on my program goes up or down. How should I do that? Thanks in advance.

I'm trying to trigger an output when an integer number on my program goes up or down. How should I do that? Thanks in advance.