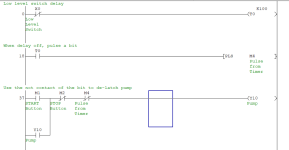

I do agree, normally I would just put the low level timer contact in the pump logic so it cannot be started until at least above low level (normally I would have a latch driven off two timers on & off so that the pump will not run until the level has been on enough to cover the probe), again to stop the pump running & stopping after a second or two. in other words a de-bounce on true & false, however, the OP wants for some reason to reset the timer (low level), I have no idea why, as far as I'm concerned you should not start the pump if below low level, but that appears to be what he want's rightly or wrongly.

It does appear from what bits of logic I have seen in his program it has not been thought out very well, there is quite a bit of I/O to make this complete process run without operator intervention, however, there seems to be lots of operator operations for example, they start/enable pumps etc. via operator interventions on the HMI, why not just one start then let the logic control the process, generate operator prompts for intervention so for example operator presses start, the tank fills to level, then allows cooling water to circulate, wait until at running temperature then allow process testing to begin. but from what I have seen this is not the case, however, there could be reasons.