Hello gentlemen,

A few questions regarding single phase motors:

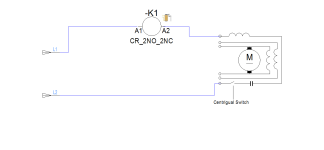

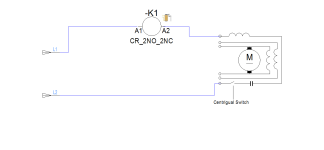

1- Would a relay wired as per attachment work? The idea (not new) is for the relay to energize for as long as the motor is stopped and the centrifugal switch is closed. I will solder a resistor across the capacitor to prevent the relay from shattering(also not new , seen it before with and without). I can get in the motor and wire the A2 of the relay coil directly to the other side of the switch but I would rather use the existing motor leads coming to the control panel.

2-What is a single phase instant reverse motor. Seen them, used them but haven't been able to get much information on how they're built nor can I get schematics for them.

3-Sigle phase dual speed motors: Similar question to the question above, how are they built and where can I get schematics for them.

Thanks

A few questions regarding single phase motors:

1- Would a relay wired as per attachment work? The idea (not new) is for the relay to energize for as long as the motor is stopped and the centrifugal switch is closed. I will solder a resistor across the capacitor to prevent the relay from shattering(also not new , seen it before with and without). I can get in the motor and wire the A2 of the relay coil directly to the other side of the switch but I would rather use the existing motor leads coming to the control panel.

2-What is a single phase instant reverse motor. Seen them, used them but haven't been able to get much information on how they're built nor can I get schematics for them.

3-Sigle phase dual speed motors: Similar question to the question above, how are they built and where can I get schematics for them.

Thanks