HoldenC

Member

I need a little help with a project I have been thinking about.

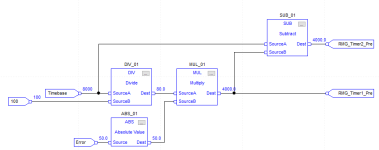

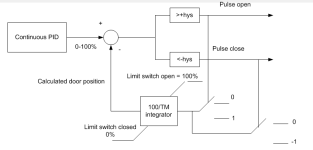

We have a belt line that is fed by a gravity door (pretty much a hydraulic gate in the ceiling). This gravity door gets plugged with material and the operator has to keep opening it up to 100% every few minutes to get it to start feeding again. I was wondering if it was possible to automate this process.

I was going to use the belt amps as a PV for this loop. The operators can adjust tonnage faster from the belt amps, rather than waiting for the material to hit the scales about 4 mins away.

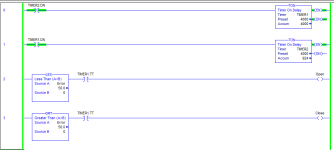

Here is my problem. The gravity door is controlled by 2 PLC outputs. One is for closed, and one is for open. Im not sure how I could program a PID loop for this with 2 outputs.

I can upload a PDF of the logic if anyone needs it.

We have a belt line that is fed by a gravity door (pretty much a hydraulic gate in the ceiling). This gravity door gets plugged with material and the operator has to keep opening it up to 100% every few minutes to get it to start feeding again. I was wondering if it was possible to automate this process.

I was going to use the belt amps as a PV for this loop. The operators can adjust tonnage faster from the belt amps, rather than waiting for the material to hit the scales about 4 mins away.

Here is my problem. The gravity door is controlled by 2 PLC outputs. One is for closed, and one is for open. Im not sure how I could program a PID loop for this with 2 outputs.

I can upload a PDF of the logic if anyone needs it.