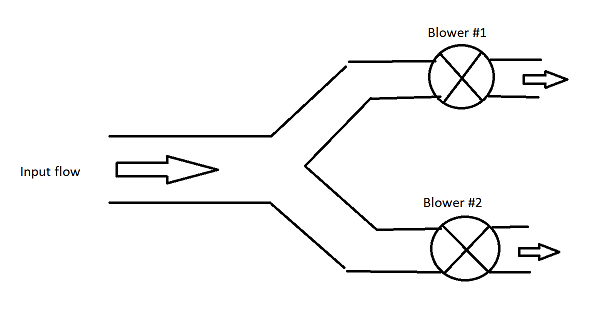

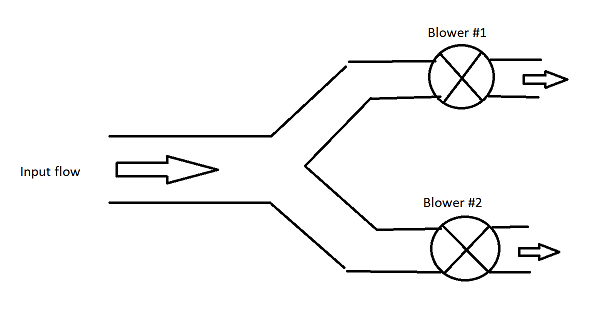

I have the control system that should control two blowers by one common input flow set point. I painted the simple picture, see the attachment.

What is the best practice for such a control loop? Is it one PID? Is it two separate PIDs that have the same SP? Maybe have I do one main PID that controls two cascaded PIDs? Or something else?

Could anyone let me links, references, articles, etc. that could clarify how to design such control systems?

What is the best practice for such a control loop? Is it one PID? Is it two separate PIDs that have the same SP? Maybe have I do one main PID that controls two cascaded PIDs? Or something else?

Could anyone let me links, references, articles, etc. that could clarify how to design such control systems?