Hello to all,

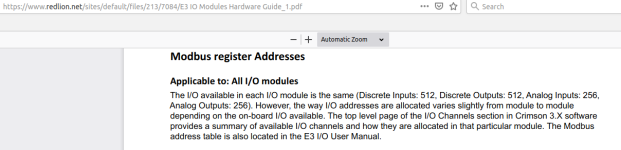

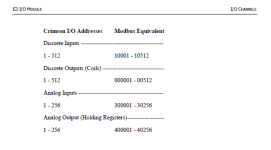

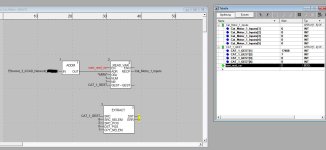

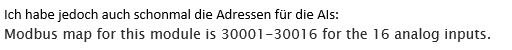

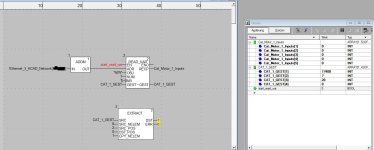

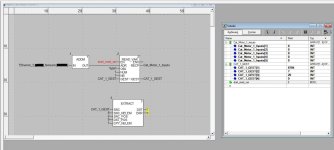

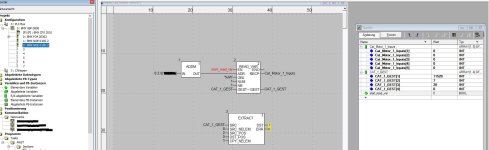

I´m new to the forum and looking for some help to setup an Schneider Electric M340- NOE0100 together with an RedLion E3-16ISOTC. In a view words I would like to use the I/O Scanner of the NOE to read the thermoelements connected to the RedLion E3 Module. Has someone some knowledge for the combination? I`m struggling to setup the I/O Scanner correct to read the analogue inputs 1-16 of the E3 Module.

Kind regards,

Frank

I´m new to the forum and looking for some help to setup an Schneider Electric M340- NOE0100 together with an RedLion E3-16ISOTC. In a view words I would like to use the I/O Scanner of the NOE to read the thermoelements connected to the RedLion E3 Module. Has someone some knowledge for the combination? I`m struggling to setup the I/O Scanner correct to read the analogue inputs 1-16 of the E3 Module.

Kind regards,

Frank