grnick50

Lifetime Supporting Member

Hello all,

I have a hot water network (district heating) that is driven by VSDs trying to maintain the Differential pressure of the network at a certain SP. Generally the process is very slow. The DP is collected at a remote location (worst DP branch) and it is transmitted to the PLC controlling the pumps via GPRS. The Actual DP is collected every 30-60 seconds and it is defined by the user.

My concern is has to do with the control method I should follow.

If I were to choose a PID control then my concern is that the PV is collected every minute and so I guess that would not work as it is not real time data.

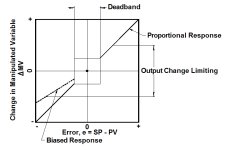

The second method I am considering, that has been used by other system integrators is some sort of step control.

I have a DP setpoint, the actual DP, a deadband and an evaluation time. I do a comparison to check if the actual DP is outside the DP+/-Deadband zone. If I am below the DP SP then I add step (say 5%) to the Pump SP. If I am below the DP SP I subtract the same step from pump SP. If I am within the deadband zone, I do nothing. This calc is repeated cyclicaly at a time set as the evaluation time (say 30sec).

This method is reported to have good results at similar installations.

What are your thoughts about this? Can you think of a better way?

I have a hot water network (district heating) that is driven by VSDs trying to maintain the Differential pressure of the network at a certain SP. Generally the process is very slow. The DP is collected at a remote location (worst DP branch) and it is transmitted to the PLC controlling the pumps via GPRS. The Actual DP is collected every 30-60 seconds and it is defined by the user.

My concern is has to do with the control method I should follow.

If I were to choose a PID control then my concern is that the PV is collected every minute and so I guess that would not work as it is not real time data.

The second method I am considering, that has been used by other system integrators is some sort of step control.

I have a DP setpoint, the actual DP, a deadband and an evaluation time. I do a comparison to check if the actual DP is outside the DP+/-Deadband zone. If I am below the DP SP then I add step (say 5%) to the Pump SP. If I am below the DP SP I subtract the same step from pump SP. If I am within the deadband zone, I do nothing. This calc is repeated cyclicaly at a time set as the evaluation time (say 30sec).

This method is reported to have good results at similar installations.

What are your thoughts about this? Can you think of a better way?