hi, i'm new to PLC and just found this website today, i'm so excited to see this website  okay, i'm studying degree in real estate, but my company is doing a lot BAS system, we use most DDCs not PLCs, eventually no one in our company knows PLCs.

okay, i'm studying degree in real estate, but my company is doing a lot BAS system, we use most DDCs not PLCs, eventually no one in our company knows PLCs.

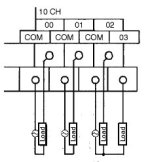

recently our company got a new project, and it was handled to me, the customer insist to use PLCs, so we approched local Omron vender, they recommanded us to use a CJ1M PLC as a master, 10 CPM1A PLCs as slaves, all together there are 11 PLCs in this project.

i think the slave PLCs are easy to program, mostly we do monitoring only, here comes the problems,

the CJ1M will be the master PLC, it has 2 additional modules each has a 422 and 232 port, they will be linked to 4 network, each network will have 2,3 CPM1A PLC. so do i still use CX programmer to program CJ1M? how do i set it up as the master collecting information and transfer to a NS 12" PT?

i think PLC ladder program is harder than DDC's FBD program we are using, but it's quite interesting and challeging.

hope i can get a more clear image about this project asap.

thanks,

recently our company got a new project, and it was handled to me, the customer insist to use PLCs, so we approched local Omron vender, they recommanded us to use a CJ1M PLC as a master, 10 CPM1A PLCs as slaves, all together there are 11 PLCs in this project.

i think the slave PLCs are easy to program, mostly we do monitoring only, here comes the problems,

the CJ1M will be the master PLC, it has 2 additional modules each has a 422 and 232 port, they will be linked to 4 network, each network will have 2,3 CPM1A PLC. so do i still use CX programmer to program CJ1M? how do i set it up as the master collecting information and transfer to a NS 12" PT?

i think PLC ladder program is harder than DDC's FBD program we are using, but it's quite interesting and challeging.

hope i can get a more clear image about this project asap.

thanks,